Industrial Machine Manufacturing for Bulk Bag Packaging Solutions

In industries handling heavy and high-volume materials, efficient packaging is essential to ensure product safety, minimize losses, and streamline logistics. Industrial machine manufacturing plays a crucial role in delivering reliable bulk bag packaging solutions that meet modern production demands. Stitch Experts is a trusted name in industrial machine manufacturing, providing robust and high-performance machines designed for bulk bag packaging across diverse industries. Why Industrial Machine Manufacturing Matters Bulk packaging operations require machines that can perform consistently under heavy loads and continuous use. High-quality machine manufacturing ensures: Investing in reliable machinery helps businesses maintain productivity and protect their products during storage and transportation. Features of Bulk Bag Packaging Machines Stitch Experts manufactures machines equipped with advanced features such as: ✔ Heavy-Duty Construction Built with reinforced steel frames for stability and durability in harsh industrial environments. ✔ Precision Stitching Technology Ensures uniform, high-strength stitching for woven, laminated, paper, and polypropylene bags. ✔ High-Speed Operation Designed to support high production rates without compromising stitching quality. ✔ Conveyor Integration Compatible with belt conveyors, inclined conveyors, and automated packaging lines. ✔ Operator-Friendly Design Simple controls, safety features, and low maintenance requirements. Applications Across Industries Our bulk bag packaging machines are widely used in: Each solution is tailored to meet industry-specific packaging challenges. Customization Options for Industrial Needs Every packaging operation is unique. Stitch Experts offers customized machine manufacturing based on: Customized solutions improve efficiency and ensure seamless operations. Benefits of Choosing Stitch Experts Proven Manufacturing Expertise Decades of experience in industrial stitching and packaging machinery. Reliable Performance Machines designed for continuous 24/7 industrial use. Cost-Effective Solutions Reduced downtime, maintenance, and labor costs. Strong After-Sales Support Technical assistance and service to ensure uninterrupted operations. How Industrial Machines Improve Business Efficiency High-quality bulk packaging machines help businesses: Future of Industrial Machine Manufacturing With advancements in automation and smart technology, industrial machine manufacturing is evolving to include: Stitch Experts continues to innovate to meet the growing demands of modern packaging industries. Conclusion Industrial machine manufacturing is the backbone of efficient bulk bag packaging. With a commitment to durability, precision, and innovation, Stitch Experts delivers high-performance machines that help industries achieve reliable and cost-effective packaging solutions. If you are looking for trusted bulk bag packaging machinery, Stitch Experts is your dependable manufacturing partner.

Manufacturing Machines for Heavy-Duty Bulk Bag Packaging

Manufacturing Machines for Heavy-Duty Bulk Bag Packaging Industries dealing with heavy and large-volume products require packaging systems that are reliable, durable, and capable of handling continuous operations. Heavy-duty bulk bag packaging machines play a critical role in ensuring product safety, minimizing losses, and maintaining efficiency throughout the supply chain. At Stitch Experts, we specialize in manufacturing machines for heavy-duty bulk bag packaging, engineered to meet the toughest industrial demands with unmatched precision and durability. What Is Heavy-Duty BulkBag Packaging? Heavy-duty bulk bag packaging is used for products that are: These bags are commonly used for packaging materials such as cement, grains, fertilizers, chemicals, minerals, animal feed, and construction materials. The machines used must withstand heavy loads while delivering consistent stitching and sealing quality. Importance of Heavy-Duty Machine Manufacturing Manufacturing machines for bulk bag packaging requires specialized engineering and material selection. Poor-quality machines can result in: Stitch Experts focuses on precision manufacturing to ensure long-lasting performance even in demanding industrial environments. Manufacturing Excellence at Stitch Experts Every machine manufactured at Stitch Experts goes through a rigorous process that includes: 1. Robust Structural Design Heavy-duty frames are fabricated using high-grade steel to ensure: 2. Precision Stitching Mechanisms Our machines are equipped with advanced stitching heads that deliver: 3. High-Quality Components We use premium motors, bearings, and mechanical parts that ensure: Key Features of Heavy-Duty Bulk Bag Packaging Machines Applications Across Industries Stitch Experts’ heavy-duty bulk bag packaging machines are widely used in: Each machine is designed to handle specific packaging challenges faced by these industries. Customization for Industrial Requirements We understand that every packaging operation is unique. Stitch Experts offers customized machine manufacturing based on: This ensures optimal performance and efficiency. Benefits of Choosing Stitch Experts Why Heavy-Duty Packaging Machines Matter for Business Growth Investing in high-quality bulk bag packaging machines leads to: Stitch Experts machines help businesses scale operations while maintaining packaging integrity. Conclusion Manufacturing machines for heavy-duty bulk bag packaging requires expertise, precision, and a deep understanding of industrial needs. Stitch Experts delivers robust, reliable, and high-performance packaging machines that industries can depend on for consistent results and long-term value. If your business demands strength, durability, and efficiency in bulk packaging, Stitch Experts is your trusted manufacturing partner.

How Industrial Machine Manufacturing Drives Efficiency in Bulk Packaging Operations

How Industrial Machine Manufacturing Drives Efficiency in Bulk Packaging Operations Industrial packaging operations rely heavily on well-engineered machines to maintain speed, accuracy, and consistency. At Stitch Experts, we focus on manufacturing industrial machines that are specifically designed to handle bulk product packaging with maximum efficiency and reliability. Role of Machine Manufacturing in Bulk Packaging High-quality machine manufacturing ensures: Our machines are designed to perform continuously in high-load industrial environments. Engineering Excellence at Stitch Experts Each machine manufactured by Stitch Experts is built with: This approach guarantees consistent performance even in demanding applications. Applications Across Industries Our industrial machines are widely used in: Advantages of Choosing Our Manufacturing Solutions Conclusion Efficient bulk packaging begins with strong machine manufacturing. Stitch Experts delivers industrial machines that empower businesses to improve productivity while maintaining packaging quality and safety.

Revolutionizing Industrial Packaging with Advanced Bag Handling & Stitching Systems by Stitch Experts

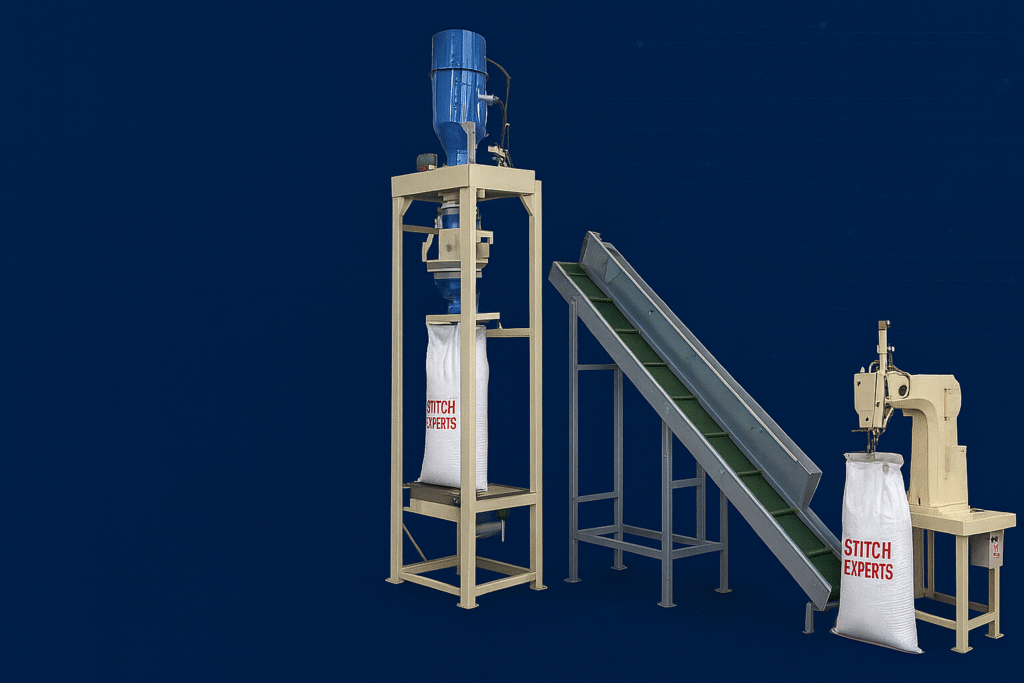

In today’s competitive industrial ecosystem, packaging is no longer just a finishing step—it is a critical component that directly impacts product safety, operational efficiency, cost control, and brand reputation. Industries dealing with bulk materials such as grains, cement, fertilizers, chemicals, animal feed, sugar, and minerals require highly reliable, precise, and durable packaging solutions. This is where advanced bag handling and stitching systems play a transformative role. For over three decades, Stitch Experts (India) has been at the forefront of this transformation, delivering innovative, dependable, and performance-driven bag handling solutions to industries across India and international markets. The Evolution of Industrial Packaging Traditional packaging methods relied heavily on manual labor, basic machinery, and inconsistent processes. While they served their purpose in the past, modern industries now demand: With increasing production volumes and stricter quality standards, businesses have shifted toward automated and semi-automated bag filling, stitching, and conveying systems. This shift has redefined packaging efficiency and reliability. Stitch Experts (India): A Legacy of Innovation Since 1992 Established in 1992, Stitch Experts (India) began with a clear vision—to revolutionize stitching technology and set new benchmarks in bag handling systems. Over the years, the company has grown into a trusted name known for engineering excellence, continuous innovation, and customer-centric solutions. Key Milestones: This growth reflects not only technological advancement but also long-term trust built with clients across diverse industries. Comprehensive Range of Bag Handling Solutions Stitch Experts offers a complete ecosystem of bag handling and industrial packaging machines, designed to work seamlessly together for optimal efficiency. 1. Bag Closing Machines Bag closing machines are the backbone of secure packaging. Stitch Experts’ machines ensure: These machines are widely used in agriculture, food processing, cement, chemicals, and mining industries. 2. Bag Filling Machines Accuracy in filling is critical to reduce losses and maintain compliance with weight standards. Stitch Experts’ bag filling machines are engineered to deliver: Whether semi-automatic or fully automated, these machines help industries maintain consistency and efficiency. 3. Conveyor Belt Systems Material movement is just as important as filling and stitching. Stitch Experts provides a wide range of conveyor belt systems, including: These systems enable smooth transportation of bags between different stages of packaging, reducing manual handling and improving workplace safety. 4. Advanced Bagging Machines For industries seeking higher automation, advanced bagging machines offer: These machines are ideal for large-scale manufacturing and export-oriented units. Why Automation in Bag Handling Is the Future With rising labor costs, demand fluctuations, and increasing competition, automation has become a necessity rather than a luxury. Benefits of Automated Bag Handling Systems: Stitch Experts designs its systems keeping future-readiness in mind, ensuring clients stay ahead of industry trends. Industry Applications Served by Stitch Experts Stitch Experts’ solutions are trusted across a wide spectrum of industries, including: Each industry has unique packaging challenges, and Stitch Experts addresses them with customized solutions tailored to specific operational requirements. Commitment to Quality, Durability & Precision One of the defining strengths of Stitch Experts is its uncompromising focus on quality. Every machine is: This commitment ensures long machine life, minimal downtime, and maximum return on investment for clients. Customer-Centric Approach & After-Sales Support Beyond manufacturing, Stitch Experts believes in building long-term partnerships. The company offers: This holistic approach has earned Stitch Experts a loyal client base and repeat customers across India and abroad. Innovation Driven by Real-World Challenges Innovation at Stitch Experts is driven by on-ground industrial challenges. Continuous R&D helps the company: By combining advanced technology with practical design, Stitch Experts ensures machines deliver real value on the shop floor. Why Choose Stitch Experts? When industries choose Stitch Experts, they gain more than just machines—they gain a reliable packaging partner. Key Reasons Clients Trust Stitch Experts: Looking Ahead: The Future of Bag Handling Technology As industries move toward smart factories and Industry 4.0, bag handling systems will continue to evolve. Stitch Experts is actively aligning its innovations with: The goal remains the same—to empower industries with packaging solutions that are efficient, reliable, and future-ready. Conclusion In an era where efficiency, accuracy, and reliability define industrial success, Stitch Experts (India) stands as a symbol of trust and innovation in bag handling and stitching systems. With a legacy built since 1992, a commitment to quality, and a forward-looking approach, Stitch Experts continues to empower industries with packaging solutions that deliver measurable results. Whether you are upgrading an existing packaging line or setting up a new facility, Stitch Experts offers the expertise, technology, and support needed to take your operations to the next level.

Revolutionizing Industrial Packaging: The Complete Guide to Modern Bag Handling & Stitching Systems (2025 Update)

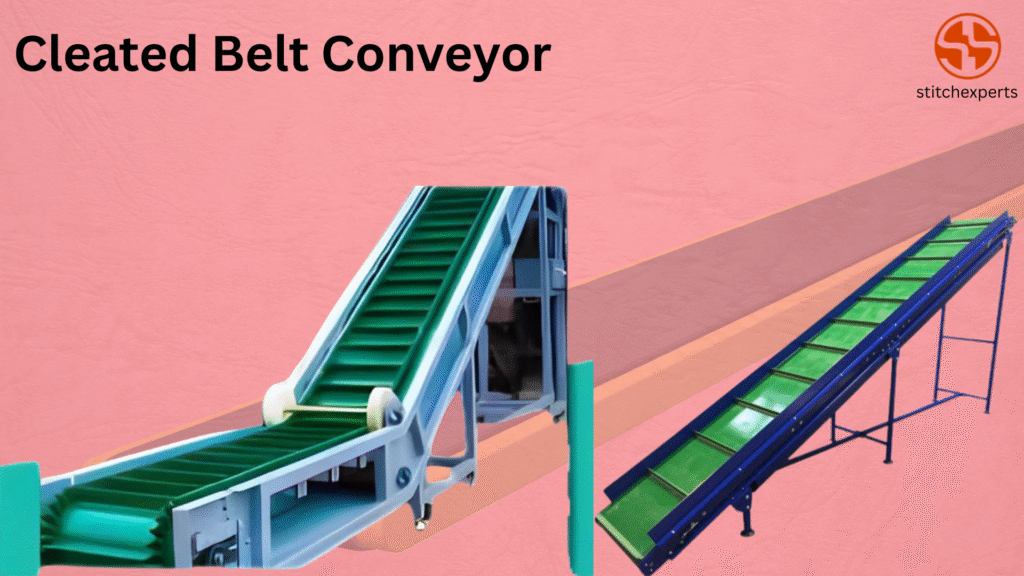

In today’s fast-paced industrial environment, packaging is no longer just the final step in the production cycle—it has become a critical pillar of quality, efficiency, and safety. Industries handling grains, chemicals, fertilizers, animal feed, cement, food products, and construction materials depend heavily on reliable bag-handling systems to streamline operations and minimize labor costs. As technology continues to evolve, advanced bag filling machines, bag closing machines, conveyors, and automation solutions are transforming how factories operate in 2025. For more than three decades, Stitch Experts (India) has played a pioneering role in modernizing industrial packaging. Since its establishment in 1992, the company has delivered high-precision, durable, and innovative machines that redefine the standards of bag filling, stitching, sealing, and handling. This blog explores the latest trends in bag-handling technology and how these solutions empower industries with unmatched precision and productivity. 1. Understanding Industrial Bag Handling Systems Bag handling refers to the series of processes involved in filling, stitching, sealing, transporting, and stacking industrial bags. A complete system may include: Modern industries require machines that are fast, accurate, safe, and capable of handling different materials. This is where Stitch Experts’ systems stand out—built for durability, adaptability, and long-term performance. 2. Growth of Automation in Bag Handling (2025 Market Outlook) The industrial packaging landscape has undergone a massive shift in the last five years. With the rising demand for higher throughput and minimal manpower, automation has taken center stage. Key reasons for this transformation include: Industries now prefer automated bag filling and stitching systems that deliver accuracy, reduce wastage, and enhance the overall efficiency of packaging operations. 3. Bag Filling Machines — Precision at Its Best A bag filling machine is the heart of any industrial packaging line. Stitch Experts’ advanced bag filling machines are engineered to provide: a.) High Filling Accuracy Whether you are handling powders, granules, seeds, or construction materials, precise weight measurement ensures minimal product loss. b.) Compatibility with Multiple Bag Types c.) Customizable Filling Speeds From small capacity requirements to heavy-duty manufacturing setups, the machines cater to diverse production volumes. d.) Dust-Free Operation Essential for cement, chemicals, fertilizers, and food-grade applications. Why Industries Prefer Stitch Experts Bag Filling Machines Bag filling has now become faster, safer, and more efficient than ever before. 4. Bag Closing Machines — Enhancing Safety and Durability Once the bag is filled, the next crucial step is closing and sealing it. Since 1992, Stitch Experts has been a market leader in bag closing machines, known for their innovation and reliability. Types of Bag Closing Machines Offered: Key Benefits: With 1,500+ successful installations across India and abroad, the brand is widely trusted in agriculture, chemical, pharmaceutical, animal feed, FMCG, and construction material industries. 5. Conveyor Belt Systems — Streamlining Material Movement Conveyors are a backbone of modern factories. Stitch Experts’ conveyor belt systems ensure seamless material movement, reducing manual labor and operational downtime. Features of a High-Quality Conveyor System Types of Conveyor Systems Available: Cleated conveyors, in particular, have gained massive demand in 2025 for moving bags vertically without slippage—ideal for factories with space constraints. 6. How Modern Bag Handling Systems Increase Productivity Industries are rapidly adopting automated and semi-automated systems due to the range of benefits they offer. 1. Reduced Labor Cost Machines handle repetitive and heavy tasks, reducing dependence on manual labor. 2. Higher Production Speed Automated bag handling systems increase output by 30–60%. 3. Improved Safety No physical strain on workers, reducing workplace injuries. 4. Better Accuracy & Consistency Machines ensure uniform filling, stitching, and sealing every time. 5. Lower Product Wastage Accurate machines minimize spillage and weight variation. 6. Improved Production Workflow Conveyors and handling systems streamline the entire packing cycle. 7. Why Stitch Experts Remains the Industry Leader (Since 1992) Stitch Experts is not just a machine manufacturer—it is a complete solution provider for industrial bag handling. Over the years, the brand has built a strong reputation based on: a.) Decades of Expertise Serving industries for more than 33 years, delivering trusted solutions worldwide. b.) 1,500+ Installations Proof of reliability and customer satisfaction across India and abroad. c.) Customized Solutions Machines designed specifically for industry demands such as agriculture, cement, chemical, FMCG, and construction sectors. d.) Advanced Technology Continuous innovation to meet the evolving needs of industrial automation. e.) World-Class After-Sales Support A dedicated support team for installation, maintenance, and quick troubleshooting. f.) Export Quality Manufacturing Machines built with high precision and international standards. 8. Future Trends in Bag Handling & Industrial Packaging As we head into the future, the demand for smarter and more automated solutions will only rise. Here are the major trends shaping the industry: 1. IoT & Smart Monitoring Real-time data tracking for machine performance, speed, and efficiency. 2. Fully Automated Packaging Lines From filling to palletizing—zero manual involvement. 3. Energy-Efficient Machines New systems that reduce power consumption while maintaining performance. 4. Eco-Friendly Packaging Materials Machines compatible with recyclable and biodegradable bags. 5. High-Speed Stitching Systems Designed to meet the rapidly growing packaging demands in India. Companies adopting these innovations will stay ahead of competition while ensuring maximum operational efficiency. 9. Final Thoughts — Build a Smarter, Faster & More Efficient Packaging Line Bag handling and stitching remain essential processes for multiple industries. With the rise of automation and technological advancements, factories now have access to highly efficient machines that increase productivity, reduce labor costs, and improve overall operations. For businesses looking to upgrade their packaging systems, Stitch Experts (India) stands as a trusted partner—offering reliable, high-performance, and cost-effective solutions backed by decades of expertise. Whether you need:a.) Bag filling machinesb.) Bag closing machinesc.) Conveyor belt systemsd.) Industrial stitching solutionse.) Customized material-handling equipment Stitch Experts ensures quality, precision, and long-term durability you can trust.

Trends in Bag-Handling Automation: What’s New in 2025

1. Introduction Bag-handling automation refers to the machines and systems used for filling, stitching, sealing, transporting, and palletizing industrial bags. In 2025, this sector is evolving rapidly due to rising labor costs, the need for higher efficiency, stricter quality standards, and the demand for sustainable packaging. Companies in agriculture, chemicals, construction, food processing, and packaging are shifting toward automated equipment to stay competitive. For manufacturers of bag-closing and stitching machines, these trends open doors for innovation and growth. 2. AI & Predictive Maintenance in Bag-Handling Machines Artificial Intelligence is becoming a core part of modern packaging automation. Machines equipped with smart sensors can monitor stitch tension, thread quality, motor temperature, and vibration levels. Instead of waiting for a breakdown, predictive maintenance alerts operators early when a needle is wearing out, a thread path is obstructed, or a component needs lubrication. This reduces downtime, improves machine longevity, and keeps the production line running smoothly. 3. Rise of Cobots and Robotics in Packaging Lines Collaborative robots (cobots) are transforming bag-handling and packaging. These robots are safe to work around humans and can handle repetitive, heavy tasks such as: Cobots reduce physical strain on workers, improve consistency, and keep production running even during labor shortages. Modern robotic systems can also adapt to different bag sizes, weights, and materials without lengthy changeover times. 4. IoT, Real-Time Monitoring & Smart Factory Integration Internet of Things (IoT) technology is making bag-handling machines “connected.” With real-time dashboards, supervisors can see: By integrating these machines with ERP, MES, and SCADA systems, factories gain full visibility of their packaging lines. This enables smarter planning, reduced waste, and better coordination across departments. 5. Sustainability & Eco-Friendly Automation Sustainability is shaping the future of packaging. Manufacturers are shifting to machines that can: Energy-efficient motors, intelligent power management, and optimized stitching mechanisms are becoming standard in new systems. 6. Modular & Scalable Bag-Handling Systems Instead of buying large, rigid machines, companies now prefer modular designs that can be expanded or reconfigured as production needs grow. Modular systems offer: This approach is especially beneficial for small and medium enterprises (SMEs) that want automation but need to manage cash flow. 7. Vision Systems & Smart Quality Control Vision-based AI systems are becoming essential for quality checking in packaging lines. These systems use high-resolution cameras to inspect: If a defect is found, the machine can automatically stop, slow down, or correct the stitching tension. This reduces rejected bags and ensures consistent packaging quality. 8. Human–Machine Collaboration & Safety Enhancements Automation is not replacing humans completely — instead, machines are working alongside people. In 2025, bag-handling systems focus heavily on operator safety and comfort. New machines include: Workers are shifting from physically intense tasks to supervisory roles where they manage automated systems. 9. Next-Generation Robotics & Research Innovations Cutting-edge research is pushing the limits of automation. Advanced robots are being developed to handle flexible, deformable bags with greater accuracy. These systems can dynamically adjust based on bag weight, shape, and movement. Future robotics might include: These innovations will pave the way for fully autonomous bag-handling lines. 10. Challenges in Adopting Modern Automation Despite the benefits, companies face challenges such as: However, hybrid automation models (part human, part machine) make the transition smoother and more affordable. 11. What This Means for Bag-Closing Machine Manufacturers For companies manufacturing bag-handling and stitching machines, these trends create strong opportunities: Manufacturers who adapt quickly will stay ahead of competitors and meet emerging global standards. 12. Conclusion Bag-handling automation in 2025 is more intelligent, sustainable, and connected than ever before. Industries are adopting AI-driven maintenance, robotic handling, IoT dashboards, vision-based quality control, and modular designs. These trends help factories improve production efficiency, reduce downtime, cut operational costs, and prepare for future challenges. Businesses that invest in these advancements now will gain a long-term competitive advantage — achieving higher throughput, better safety, and improved product quality.

Unlock Efficiency & Elevation: Why a Cleated Belt Conveyor from Stitch Experts Is Your Ideal Material-Handling Solution

Unlock Efficiency & Elevation: Why a Cleated Belt Conveyor from Stitch Experts Is Your Ideal Material-Handling Solution Introduction: The Need for Smarter Material Handling In modern manufacturing and industrial setups, efficient material handling is the key to productivity. When products, raw materials, or components need to move between different levels or along inclined paths, a standard conveyor often falls short. That’s where a Cleated Belt Conveyor makes all the difference. At Stitch Experts, we design and manufacture Cleated Belt Conveyors that offer reliable material elevation, smooth transfer, and enhanced operational efficiency. Built with precision engineering and high-quality materials, our conveyors ensure the uninterrupted movement of goods in industries ranging from packaging and pharmaceuticals to food processing and logistics. What Is a Cleated Belt Conveyor? A Cleated Belt Conveyor is a type of conveyor system designed with vertical cleats or barriers attached to the belt surface. These cleats help carry materials up an incline, preventing slippage and ensuring controlled movement even when transporting items at steep angles. This makes Cleated Belt Conveyors ideal for moving products like grains, granules, bottles, cartons, or any component that might roll or slide on a flat belt. With a range of cleat designs and customizable configurations, Stitch Experts offers solutions tailored to your industrial application. How Cleated Belt Conveyors Improve Efficiency When it comes to conveying materials, efficiency depends on consistent movement, minimal downtime, and optimized design.Here’s how our Cleated Belt Conveyors help industries achieve that: Smooth Incline Conveying:Cleats provide grip and stability, enabling the belt to move products smoothly even on steep slopes. Reduced Product Loss:By keeping materials securely in place, our Cleated Belt Conveyors minimize wastage during transport. Enhanced Throughput:With faster, continuous material flow, your production line runs more efficiently and consistently. Lower Maintenance Needs:Built from durable materials and engineered with precision, Stitch Experts conveyors reduce wear and tear, ensuring longer operational life. Customizable for Every Industry:Whether you need PVC, rubber, or modular belts — flat or inclined — we design Cleated Belt Conveyors specific to your product type and environment. Applications of Cleated Belt Conveyors Cleated Belt Conveyors are highly versatile and can be used in a wide range of sectors. At Stitch Experts, we supply conveyors to industries such as: Food Processing: Transporting grains, pulses, vegetables, or packaged items safely and hygienically. Pharmaceuticals: Handling capsules, bottles, and pouches with precision and cleanliness. Automotive: Moving small components like nuts, bolts, and plastic parts efficiently. Packaging & Logistics: Conveying boxes, cartons, and containers at multiple height levels. Agriculture: Moving seeds, fertilizers, and grains from storage to production lines. Mining & Construction: Carrying heavy or granular materials up inclines safely. Key Features of Stitch Experts Cleated Belt Conveyors 1. Robust Construction Our conveyors are built using high-grade stainless steel or mild steel frames, ensuring durability and long-term reliability in demanding industrial conditions. 2. High-Quality Belt Material We offer belts made of PVC, PU, or rubber, depending on the operational requirements. Each belt is designed to provide excellent grip, flexibility, and resistance to wear and tear. 3. Adjustable Cleat Design Cleat height and spacing can be customized to handle various material types — from fine powders to large components — ensuring smooth flow and minimal product spillage. 4. Energy-Efficient Drive System Our Cleated Belt Conveyors are equipped with advanced drive systems that consume less power while maintaining consistent performance. 5. Easy Maintenance Quick-release belt tensioning systems and easy-access components make maintenance simple, reducing downtime and keeping production on schedule. 6. Compact & Space-Saving Design Whether you need a floor-mounted or wall-supported conveyor, Stitch Experts provides designs that fit perfectly into your existing plant layout. Why Choose a Cleated Belt Conveyor Over a Flat Conveyor? While both conveyors move materials effectively, Cleated Belt Conveyors offer added advantages in scenarios where elevation, product containment, or friction is critical. Feature Cleated Belt Conveyor Flat Belt Conveyor Incline Handling Excellent – prevents slippage Limited capability Material Stability High – due to cleats Moderate Customization Highly customizable Basic Ideal for Granular, inclined, or heavy items Flat surface transport Efficiency Superior for inclined operations Standard When productivity, safety, and space optimization matter, Stitch Experts’ Cleated Belt Conveyors outperform traditional systems. Why Comfort, Safety & Performance Matter in Material Handling In industries where speed meets precision, having reliable equipment ensures smoother workflows and safer environments. Our Cleated Belt Conveyors are engineered not just for function, but for operator comfort and overall plant safety — minimizing manual labor and potential hazards. Customization Options from Stitch Experts At Stitch Experts, every conveyor is built to suit your exact needs. Our customization options include: Belt width, length, and cleat height variations Adjustable speeds and incline angles Choice of materials (stainless steel, mild steel, or aluminum frames) Integration with sensors, hoppers, and weighing systems Modular or fixed installation designs This flexibility makes our Cleated Belt Conveyors a preferred choice across industries for both small-scale and large-scale applications. Why Choose Stitch Experts for Cleated Belt Conveyors 1. Proven Industry Experience With years of expertise in conveyor manufacturing, we understand the diverse needs of material-handling industries. 2. Quality That Speaks for Itself Every conveyor passes through strict quality checks to ensure performance, precision, and longevity. 3. Cost-Effective Solutions Our in-house production and smart design techniques ensure you get the best quality at competitive prices. 4. Comprehensive Support From design consultation to installation and after-sales service, we provide full support to ensure your conveyor system runs efficiently. 5. Innovation & Technology Stitch Experts continuously invests in advanced technologies to develop conveyors that improve productivity and energy efficiency. Conclusion: Elevate Your Production Line with Stitch Experts A Cleated Belt Conveyor is more than just a transport system — it’s a productivity booster that ensures smooth, safe, and efficient movement of materials. With their ability to handle inclined surfaces and prevent slippage, these conveyors are essential for modern industries. At Stitch Experts, our Cleated Belt Conveyors are designed with precision, durability, and performance in mind. Whether you operate in packaging, food processing, or heavy manufacturing, our conveyors deliver the reliability

Enhancing Industrial Packaging Efficiency with Advanced Bagging Machines by Stitch Experts

Enhancing Industrial Packaging Efficiency with Advanced Bagging Machines by Stitch Experts Introduction – In today’s competitive industrial landscape, packaging is no longer just the final step of production — it’s a crucial part of brand value, efficiency, and product integrity. Industrial packaging demands high precision, speed, and consistency to meet growing consumer expectations and supply chain demands. As businesses move towards automation, the role of advanced bagging machines has become indispensable. Stitch Experts, a trusted name in the field of industrial stitching and packaging machinery, is at the forefront of revolutionizing packaging operations across various industries. With their innovative range of advanced bagging machines, they empower manufacturers to enhance productivity, reduce labor dependency, and maintain exceptional product quality. This blog explores how Stitch Experts’ cutting-edge bagging machines are transforming industrial packaging efficiency through automation, precision, and innovation. 1. Understanding Bagging Machines What Are Bagging Machines? A bagging machine is a specialized piece of equipment designed to fill and seal bags efficiently, accurately, and safely. These machines are commonly used in industries dealing with powdered, granular, or bulk materials such as food grains, fertilizers, chemicals, cement, and animal feed. Bagging machines automate the filling process, ensuring each bag receives the exact quantity of product, which minimizes wastage and maximizes throughput. Depending on production requirements, bagging systems can range from manual and semi-automatic to fully automated high-speed models. Types of Bagging Machines Manual Bagging Machines – Ideal for small-scale operations where limited automation is required. Semi-Automatic Bagging Machines – These machines combine manual handling with automated weighing and sealing systems. Fully Automatic Bagging Machines – Best suited for high-volume industries. They offer precision filling, sealing, and stitching without human intervention. Applications Across Industries Agriculture & Food Processing: For packing grains, pulses, and seeds. Chemical & Fertilizer Industry: For filling powdered or granulated chemicals. Construction Materials: For cement, sand, and gypsum packaging. Animal Feed Production: Ensures consistent and contamination-free packing. Through automation and precision, bagging machines form the backbone of industrial packaging lines, helping manufacturers scale operations efficiently. 2. The Role of Bagging Machines in Industrial Packaging Industrial packaging is not just about enclosing products; it’s about ensuring protection, maintaining consistency, and optimizing logistics. Here’s how bagging machines elevate the packaging process: a. Improved Speed and Productivity Manual packaging is time-consuming and inconsistent. Automated bagging machines by Stitch Experts can fill and seal hundreds of bags per hour, significantly increasing output while maintaining accuracy. b. Accuracy and Waste Reduction Each bag is weighed with high precision. Advanced weighing systems minimize overfilling and reduce material wastage, leading to substantial cost savings over time. c. Enhanced Product Safety With controlled environments and sealed bags, contamination risks are minimized. This is particularly essential for food and pharmaceutical sectors. d. Reduced Human Error Automation replaces repetitive manual work, ensuring consistent quality and reducing dependence on skilled labor. By streamlining these packaging steps, bagging machines help manufacturers achieve faster turnarounds, higher accuracy, and better product presentation. 3. Advanced Features of Modern Bagging Machines Modern bagging systems are not just about filling and sealing — they’re about intelligent automation and data-driven efficiency. Stitch Experts integrates cutting-edge features into their machines to stay ahead of industry demands. a. Smart Control Panels Intuitive digital interfaces allow operators to monitor and adjust machine performance in real time. This ensures maximum uptime and minimal operational errors. b. Precise Weighing Mechanisms Stitch Experts’ machines use advanced weighing sensors that deliver highly accurate results, even for fine powders or lightweight materials. c. IoT and Automation Integration Smart sensors and IoT-enabled systems allow remote monitoring, predictive maintenance, and data analysis — making production lines smarter and more responsive. d. Seamless Sealing and Stitching Using robust sewing heads and sealing mechanisms, Stitch Experts ensures every bag is perfectly closed, providing durability and professional finish. e. Compatibility and Customization Each industry has unique requirements — from bag sizes to materials. Stitch Experts offers customizable machines tailored to specific packaging needs. These innovative features ensure that every packaging line operates at optimal efficiency while maintaining top-notch quality control. 4. Benefits of Using Bagging Machines by Stitch Experts Stitch Experts has earned a strong reputation for delivering reliable, efficient, and high-performance bagging machines. Let’s explore why their equipment stands out: a. Enhanced Productivity Automation drastically reduces manual intervention, allowing operations to continue seamlessly. Higher throughput equals greater profitability. b. Energy Efficiency Stitch Experts’ machines are designed with energy optimization in mind. They minimize power consumption without compromising on performance. c. Precision and Consistency Each bag receives the exact quantity of material — every single time. This level of precision enhances product uniformity and customer satisfaction. d. Durable Construction Made with high-grade materials and advanced engineering, these machines withstand continuous heavy-duty operations with minimal maintenance. e. Reduced Labor Costs By automating the packaging process, companies can optimize manpower usage and reduce operational expenses. f. Easy Maintenance and Service Support Stitch Experts provides prompt after-sales support and technical assistance, ensuring long-term machine reliability and minimal downtime. g. Real-World Impact Example Imagine a fertilizer manufacturing plant that previously relied on manual packing. After installing a Stitch Experts automatic bagging machine, their packaging speed increased by 300%, labor cost dropped by 40%, and material wastage nearly vanished. This transformation reflects how technology can redefine productivity. 5. Why Choose Stitch Experts for Your Packaging Needs A Legacy of Innovation and Quality Stitch Experts has consistently been recognized for its commitment to precision engineering and performance-driven design. Their machines embody innovation, durability, and user convenience. Comprehensive Product Range The company offers a complete suite of packaging solutions — from bag closing machines and industrial stitching heads to fully automated bagging systems — making them a one-stop solution provider. Customization Expertise Every client’s needs differ. Stitch Experts collaborates with businesses to design and build tailored bagging systems suited to specific products, bag types, and production volumes. Reliable Support and Maintenance Beyond manufacturing excellence, Stitch Experts provides reliable after-sales support, ensuring maximum uptime and consistent operational efficiency. Trusted by Leading Industries Their client portfolio spans sectors such

Stitch Experts — Empowering Industries with Precision Bag Filling

Stitch Experts — Empowering Industries with Precision Bag Filling Machine Precision, reliability, and efficiency are vital pillars in modern industrial packaging. For companies handling bulk products, maintaining accurate and consistent bag filling is not only critical for operational efficiency but also for preserving product quality, reducing wastage, and enhancing customer satisfaction. Stitch Experts, a leading name in industrial machinery, has transformed the landscape of bag filling solutions by offering precision-engineered machines, cutting-edge technology, and customized solutions tailored to diverse industrial needs. Their innovative Bag Filling Machines empower industries to streamline packaging, boost productivity, and maintain consistent quality in every operation. About Stitch Experts With years of experience in designing, manufacturing, and supplying industrial machinery, Stitch Experts has earned a reputation as a trusted partner for businesses across sectors like food processing, pharmaceuticals, agriculture, chemicals, and construction materials. The company’s focus lies in precision, reliability, and innovation, ensuring every machine meets the highest standards of performance. Stitch Experts’ key strengths include: Advanced engineering expertise in industrial packaging solutions. High-quality manufacturing processes to ensure durability and accuracy. Compliance with international quality standards. Commitment to after-sales support and customer satisfaction. By integrating technology with practical industry requirements, Stitch Experts ensures that businesses experience enhanced operational efficiency, reduced downtime, and consistent product quality. Comprehensive Product Range Stitch Experts provides a diverse range of bag filling machines to meet varying industry needs: 1. Automatic Bag Filling Machines These machines deliver high-speed, fully automated filling with precise weight measurements. They are ideal for large-scale industries like food processing, chemical manufacturing, and fertilizer packaging. Features include: PLC-controlled automation for consistent performance. High-capacity hoppers for uninterrupted operation. Accurate filling to minimize wastage. 2. Semi-Automatic Bag Filling Machines Semi-automatic systems combine manual operation with automation, providing flexibility for medium-scale industries. They: Reduce labor requirements while maintaining precision. Allow easy handling of varied bag sizes and weights. Ensure fast setup and operation. 3. Vertical Form Fill Seal (VFFS) Machines VFFS machines are designed to form, fill, and seal bags from roll films in a single process. Ideal for granular and powdered products, they: Offer high-speed operations with minimal human intervention. Guarantee airtight and secure packaging. Maintain product hygiene and quality standards. 4. Multi-Head Weigher Bag Fillers Multi-head weigher machines provide precise weight measurement using multiple hoppers for fast and efficient filling. Benefits include: High-speed packaging for granular products. Reduced product giveaway due to high weighing accuracy. Suitable for food, chemicals, and granular industrial products. 5. Customized Solutions Understanding that every industry has unique requirements, Stitch Experts offers tailor-made bag filling machines: Customizable for bag sizes, product types, and production capacity. Designed for seamless integration into existing production lines. Scalable to match growing business needs. In-Depth Features and Benefits Stitch Experts’ bag filling machines stand out due to their combination of technology, precision, and user-friendly design. Precision & Accuracy Advanced weighing systems ensure exact filling every time. Minimizes overfilling or underfilling, reducing material wastage. Critical for industries like pharmaceuticals and chemicals where precision is non-negotiable. Operational Efficiency High-speed automation increases throughput. Reduces human intervention, decreasing the chances of errors. Optimized for minimal downtime and easy maintenance. Durability & Reliability Robust construction ensures long-lasting performance even in demanding environments. Resistant to wear and tear, chemicals, and high-volume operations. User-Friendly Controls Intuitive control panels for easy setup and monitoring. Quick changeover between bag sizes and product types. Real-time feedback and alerts to enhance productivity. Energy Efficiency Machines designed to consume less power without compromising performance. Supports sustainability goals and reduces operational costs. Safety Compliance Adheres to industrial safety standards. Protects operators and ensures safe handling of materials. Technology & Innovation Stitch Experts continually invests in R&D to bring the latest technology into bag filling solutions. Automation & Smart Controls: Modern PLC-based systems allow operators to set, monitor, and adjust parameters, ensuring accurate filling every time. Multi-Functional Machines: Capable of handling multiple product types and bag formats without compromising precision. Sensors & Feedback Systems: Ensure real-time monitoring and automatic correction for deviations. Sustainability Features: Energy-efficient motors, minimal waste, and durable components reduce environmental impact. By staying at the forefront of technological advancements, Stitch Experts ensures that industries achieve faster production, minimal wastage, and consistent product quality. Comparison with Other Bag Filling Machines Stitch Experts machines offer several advantages over competitors: Feature Stitch Experts Typical Competitor Machines Advantage Precision ±0.5% ±2–3% Reduced product wastage Automation Fully automated & PLC controlled Limited automation Faster operation & less labor dependency Durability High-grade steel, long-lasting Average-grade steel Longer life and reduced maintenance Customization Fully customizable Limited options Fits unique industrial needs Support & Service Comprehensive after-sales support Limited service Reduced downtime and enhanced reliability This comparison clearly shows why industries trust Stitch Experts for critical packaging operations. Applications Across Industries Bag filling machines are crucial in multiple sectors: 1. Food Industry Filling rice, flour, sugar, spices, snacks, grains. Guarantees consistent product weight, hygiene, and packaging integrity. 2. Pharmaceutical Industry Accurate powder and granule filling. Ensures compliance with strict hygiene and safety standards. 3. Agriculture & Fertilizers Efficient packaging of seeds, grains, and fertilizers. Reduces spillage and ensures consistent weight per bag. 4. Chemicals & Construction Materials Safe handling and packaging of powders, granules, and cement. Reduces human exposure to hazardous materials. By integrating Stitch Experts’ bag filling machines, industries improve operational efficiency, maintain consistent product quality, and maximize profitability. Why Choose Stitch Experts? Stitch Experts is not just a manufacturer; it is a trusted industrial partner: Brand Reputation: Years of delivering reliable solutions. Customized Solutions: Machines tailored to client requirements. Expert Consultation: Helps businesses choose the right solution. After-Sales Service: Ensures smooth operation and minimal downtime. Proven Results: Clients report improved productivity, reduced wastage, and increased operational efficiency. Conclusion & Call to Action Stitch Experts — Empowering Industries with Precision Bag Filling symbolizes quality, reliability, and innovation in industrial packaging. Their precision-engineered bag filling machines help businesses enhance efficiency, reduce operational costs, and maintain consistent product quality. For industries looking for high-performance, durable, and technologically advanced bag filling solutions, Stitch Experts is the partner of choice. Contact

Stitch Experts: Trusted Bag Closing Machines for Efficient and Modern Packaging in India

Stitch Experts: Trusted Bag Closing Machines for Efficient and Modern Packaging in India In the fast-paced industrial sector, maintaining efficiency, accuracy, and safety in packaging operations is crucial. Stitch Experts has emerged as a leading name in India for bag closing machines, offering industrial solutions that cater to manufacturers, packaging companies, warehouses, and material handling professionals. With years of expertise and a focus on modern packaging solutions, Stitch Experts ensures that businesses can streamline their operations while maintaining high standards of quality. Bag closing machines are essential in various industries, including food processing, fertilizers, chemicals, grains, and industrial materials. They not only secure packaging but also reduce manual labor, minimize errors, and enhance overall production efficiency. By integrating advanced machinery from Stitch Experts, companies can modernize their packaging workflow and meet the growing demands of the market. Why Bag Closing Machines Are Essential for Modern Industries Efficient packaging is the backbone of modern industrial operations. Industrial bag closing machines play a pivotal role in enhancing production capacity, ensuring product safety, and maintaining consistency across batches. Below are some reasons why these machines are indispensable: 1. Improve Efficiency Manual bag closing processes can be time-consuming and inconsistent. With industrial bag closing machines, manufacturers can automate the stitching or sealing process, significantly reducing production time. This automation ensures that high-volume operations meet tight deadlines without compromising quality. 2. Ensure Accuracy and Consistency Industrial-grade bag closing machines offer precise stitching, ensuring every bag is sealed uniformly. This reduces the risk of product leakage, spoilage, or contamination. For industries handling sensitive products like chemicals or food items, consistent sealing is crucial to maintain product integrity. 3. Enhance Safety Manual bag handling and stitching can pose safety risks to workers. Automated bag closing machines minimize human intervention, reducing the chances of accidents, injuries, or repetitive strain. Modern machines are designed with safety features, making the workplace more secure. 4. Optimize Workflow By integrating bag closing machines into the production line, companies can achieve a smoother workflow. The automation allows for synchronization with other equipment, such as conveyors, filling machines, and material handling systems, creating a seamless industrial operation. Features of Stitch Experts Bag Closing Machines Stitch Experts focuses on delivering high-quality, industrial-grade bag closing machines that cater to diverse industrial requirements. Some of the key features include: 1. Durability Built with robust materials and engineering precision, Stitch Experts’ machines are designed for long-term performance even under heavy industrial use. 2. Industrial-Grade Construction These machines are constructed to withstand continuous operation in demanding industrial environments, offering reliability and minimal downtime. 3. Precision Stitching Advanced technology ensures precise stitching or sealing for every bag, which is vital for product safety and quality assurance. 4. Automation Options Stitch Experts offers both semi-automatic and fully automatic bag closing solutions, allowing industries to select machines based on their production requirements. 5. Low Maintenance and Energy Efficiency Designed to consume minimal power and require less maintenance, these machines reduce operational costs while improving overall efficiency. Bag Closing Machine Product Range Stitch Experts offers a variety of industrial bag closing machines tailored to modern packaging needs: 1. Bag Closing Machine With Belt Conveyor This model integrates a high-quality belt conveyor with the bag closing machine, allowing for seamless transportation and stitching of bags. Ideal for high-volume operations, it improves workflow efficiency and reduces manual labor. The conveyor ensures smooth handling of heavy bags and consistent stitching across batches. 2. Bag Closing Machine With Conveyor The bag closing machine with conveyor is designed for medium to large-scale industrial operations. It automates bag handling and stitching, reducing human effort and ensuring precise sealing. Compact yet robust, it can be easily integrated into existing production lines, enhancing productivity without compromising space. Comparison: Stitch Experts Machines vs Competitors When evaluating bag closing machines, businesses often compare Stitch Experts with other industrial machine providers. Here’s a quick comparison: Feature Stitch Experts Competitor A Competitor B Industrial-Grade Construction ✅ High Moderate Moderate Automation Options ✅ Semi & Fully Automatic Limited Semi-Automatic Precision Stitching ✅ Consistent Variable Moderate Maintenance ✅ Low Medium Medium Energy Efficiency ✅ High Moderate Low After-Sales Support ✅ Excellent Limited Moderate Customizable Solutions ✅ Yes No Limited This comparison clearly shows that Stitch Experts stands out in reliability, automation, and B2B support, making it the preferred choice for Indian manufacturers and packaging industries. Advantages of Choosing Stitch Experts Selecting Stitch Experts as your bag closing machine provider offers multiple advantages: 1. Trusted Manufacturer Since 1992 With decades of experience, Stitch Experts has built a strong reputation in the Indian industrial market. Their commitment to quality and innovation ensures clients receive reliable machinery. 2. Customizable Industrial Solutions Understanding that each industry has unique requirements, Stitch Experts provides tailored solutions, allowing businesses to choose machines that best fit their production needs. 3. Excellent After-Sales Service Industrial operations cannot afford downtime. Stitch Experts offers prompt after-sales service, maintenance support, and technical assistance, ensuring minimal disruption in production. 4. Proven Track Record With numerous satisfied clients across India, Stitch Experts machines have demonstrated efficiency, reliability, and durability in diverse industrial settings. Buying Guide: How to Select the Right Bag Closing Machine Choosing the ideal bag closing machine requires careful consideration of multiple factors: 1. Bag Type Consider the material (PP, HDPE, jute, or woven sacks) and size of the bags. Different machines handle specific materials more efficiently. 2. Stitching Method Evaluate whether your production requires single-needle, double-needle, or automated stitching mechanisms. Advanced machines offer flexibility for different stitching methods. 3. Production Capacity Estimate the number of bags processed daily. High-volume industries should consider fully automatic machines with integrated conveyors to handle bulk operations efficiently. 4. Automation Level Decide between semi-automatic and fully automatic machines based on labor availability and production requirements. Automation reduces manual intervention and increases consistency. 5. Energy Efficiency Select machines that consume minimal power while maintaining high output. Energy-efficient machines reduce long-term operational costs. 6. Space & Integration Ensure the machine fits your production floor layout and can integrate with other systems like filling machines,