Unlock Efficiency & Elevation: Why a Cleated Belt Conveyor from Stitch Experts Is Your Ideal Material-Handling Solution

Introduction: The Need for Smarter Material Handling

In modern manufacturing and industrial setups, efficient material handling is the key to productivity. When products, raw materials, or components need to move between different levels or along inclined paths, a standard conveyor often falls short. That’s where a Cleated Belt Conveyor makes all the difference.

At Stitch Experts, we design and manufacture Cleated Belt Conveyors that offer reliable material elevation, smooth transfer, and enhanced operational efficiency. Built with precision engineering and high-quality materials, our conveyors ensure the uninterrupted movement of goods in industries ranging from packaging and pharmaceuticals to food processing and logistics.

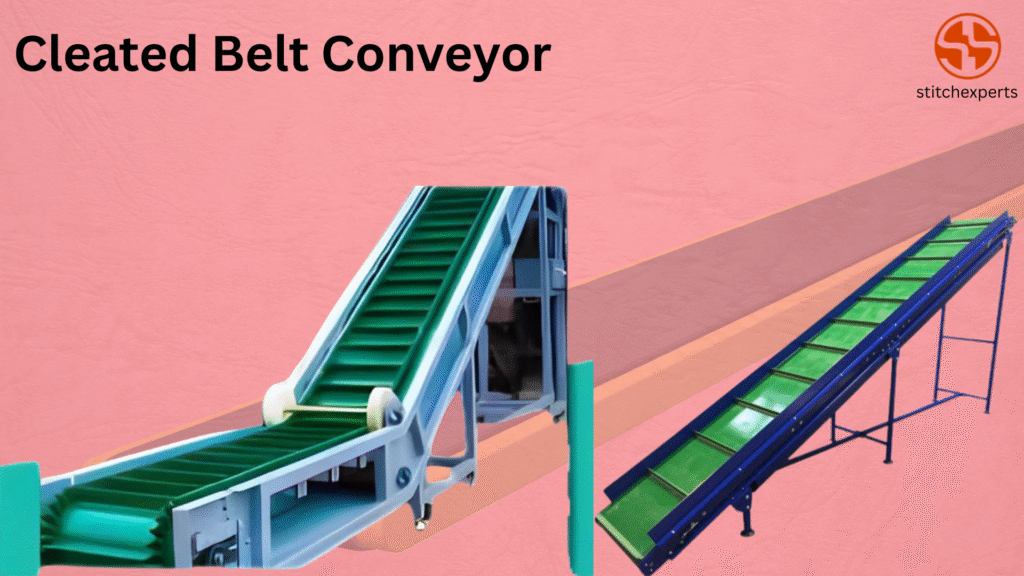

What Is a Cleated Belt Conveyor?

A Cleated Belt Conveyor is a type of conveyor system designed with vertical cleats or barriers attached to the belt surface. These cleats help carry materials up an incline, preventing slippage and ensuring controlled movement even when transporting items at steep angles.

This makes Cleated Belt Conveyors ideal for moving products like grains, granules, bottles, cartons, or any component that might roll or slide on a flat belt. With a range of cleat designs and customizable configurations, Stitch Experts offers solutions tailored to your industrial application.

How Cleated Belt Conveyors Improve Efficiency

When it comes to conveying materials, efficiency depends on consistent movement, minimal downtime, and optimized design.

Here’s how our Cleated Belt Conveyors help industries achieve that:

Smooth Incline Conveying:

Cleats provide grip and stability, enabling the belt to move products smoothly even on steep slopes.Reduced Product Loss:

By keeping materials securely in place, our Cleated Belt Conveyors minimize wastage during transport.Enhanced Throughput:

With faster, continuous material flow, your production line runs more efficiently and consistently.Lower Maintenance Needs:

Built from durable materials and engineered with precision, Stitch Experts conveyors reduce wear and tear, ensuring longer operational life.Customizable for Every Industry:

Whether you need PVC, rubber, or modular belts — flat or inclined — we design Cleated Belt Conveyors specific to your product type and environment.

Applications of Cleated Belt Conveyors

Cleated Belt Conveyors are highly versatile and can be used in a wide range of sectors. At Stitch Experts, we supply conveyors to industries such as:

Food Processing: Transporting grains, pulses, vegetables, or packaged items safely and hygienically.

Pharmaceuticals: Handling capsules, bottles, and pouches with precision and cleanliness.

Automotive: Moving small components like nuts, bolts, and plastic parts efficiently.

Packaging & Logistics: Conveying boxes, cartons, and containers at multiple height levels.

Agriculture: Moving seeds, fertilizers, and grains from storage to production lines.

Mining & Construction: Carrying heavy or granular materials up inclines safely.

Key Features of Stitch Experts Cleated Belt Conveyors

1. Robust Construction

Our conveyors are built using high-grade stainless steel or mild steel frames, ensuring durability and long-term reliability in demanding industrial conditions.

2. High-Quality Belt Material

We offer belts made of PVC, PU, or rubber, depending on the operational requirements. Each belt is designed to provide excellent grip, flexibility, and resistance to wear and tear.

3. Adjustable Cleat Design

Cleat height and spacing can be customized to handle various material types — from fine powders to large components — ensuring smooth flow and minimal product spillage.

4. Energy-Efficient Drive System

Our Cleated Belt Conveyors are equipped with advanced drive systems that consume less power while maintaining consistent performance.

5. Easy Maintenance

Quick-release belt tensioning systems and easy-access components make maintenance simple, reducing downtime and keeping production on schedule.

6. Compact & Space-Saving Design

Whether you need a floor-mounted or wall-supported conveyor, Stitch Experts provides designs that fit perfectly into your existing plant layout.

Why Choose a Cleated Belt Conveyor Over a Flat Conveyor?

While both conveyors move materials effectively, Cleated Belt Conveyors offer added advantages in scenarios where elevation, product containment, or friction is critical.

| Feature | Cleated Belt Conveyor | Flat Belt Conveyor |

|---|---|---|

| Incline Handling | Excellent – prevents slippage | Limited capability |

| Material Stability | High – due to cleats | Moderate |

| Customization | Highly customizable | Basic |

| Ideal for | Granular, inclined, or heavy items | Flat surface transport |

| Efficiency | Superior for inclined operations | Standard |

When productivity, safety, and space optimization matter, Stitch Experts’ Cleated Belt Conveyors outperform traditional systems.

Why Comfort, Safety & Performance Matter in Material Handling

In industries where speed meets precision, having reliable equipment ensures smoother workflows and safer environments. Our Cleated Belt Conveyors are engineered not just for function, but for operator comfort and overall plant safety — minimizing manual labor and potential hazards.

Customization Options from Stitch Experts

At Stitch Experts, every conveyor is built to suit your exact needs. Our customization options include:

Belt width, length, and cleat height variations

Adjustable speeds and incline angles

Choice of materials (stainless steel, mild steel, or aluminum frames)

Integration with sensors, hoppers, and weighing systems

Modular or fixed installation designs

This flexibility makes our Cleated Belt Conveyors a preferred choice across industries for both small-scale and large-scale applications.

Why Choose Stitch Experts for Cleated Belt Conveyors

1. Proven Industry Experience

With years of expertise in conveyor manufacturing, we understand the diverse needs of material-handling industries.

2. Quality That Speaks for Itself

Every conveyor passes through strict quality checks to ensure performance, precision, and longevity.

3. Cost-Effective Solutions

Our in-house production and smart design techniques ensure you get the best quality at competitive prices.

4. Comprehensive Support

From design consultation to installation and after-sales service, we provide full support to ensure your conveyor system runs efficiently.

5. Innovation & Technology

Stitch Experts continuously invests in advanced technologies to develop conveyors that improve productivity and energy efficiency.

Conclusion: Elevate Your Production Line with Stitch Experts

A Cleated Belt Conveyor is more than just a transport system — it’s a productivity booster that ensures smooth, safe, and efficient movement of materials. With their ability to handle inclined surfaces and prevent slippage, these conveyors are essential for modern industries.

At Stitch Experts, our Cleated Belt Conveyors are designed with precision, durability, and performance in mind. Whether you operate in packaging, food processing, or heavy manufacturing, our conveyors deliver the reliability your business demands.