Automatic Bag Filling Machine

Automatic Bag Filling Machine

Automatic Bag Filling Machines offer high-speed and accurate filling solutions for powders, granules, and bulk materials in packaging lines.

Send An Enquiry!

Additional Information:

Automatic Bag Filling and Sealing Machine – Efficient & Precise Packaging Solution

In industries where speed, accuracy, and efficiency are crucial, an automatic bag filling and sealing machine plays a vital role in streamlining packaging operations. Whether you deal with powders, granules, or bulk materials, this advanced machine ensures consistent and high-speed filling while minimizing waste.

At Stitch Expert India, we design and manufacture state-of-the-art automatic bag filling and sealing machines to meet the demands of food processing, agriculture, pharmaceuticals, chemicals, and more.

What is an Automatic Bag Filling and Sealing Machine?

An automatic bag filling and sealing machine is a fully automated system designed to fill and seal bags with precision and efficiency. It eliminates manual handling, reducing labor costs and improving overall productivity.

This machine is ideal for industries that require bulk packaging while maintaining quality and uniformity.

Key Features of Our Automatic Bag Filling and Sealing Machine

✔ High-Speed Filling – Capable of handling large volumes efficiently.

✔ Accurate Weighing & Dispensing – Reduces material waste and ensures precision.

✔ Fully Automated Operations – Requires minimal human intervention.

✔ User-Friendly Interface – Easy to operate with touchscreen controls.

✔ Customizable for Various Bag Sizes – Supports multiple bag types and materials.

✔ Robust & Durable Construction – Built with high-quality stainless steel for long-term performance.

✔ Integration with Existing Production Lines – Ensures seamless workflow.

With these features, our bag filling and sealing machine optimizes packaging efficiency and product safety.

How Does an Automatic Bag Filling and Sealing Machine Work?

The automatic bag filling and sealing process consists of the following steps:

1️⃣ Bag Placement – The system automatically picks and positions the bag.

2️⃣ Weighing & Dispensing – The material is precisely measured and dispensed into the bag.

3️⃣ Bag Filling – The bag is filled with the required quantity of product.

4️⃣ Sealing & Closing – The bag is securely sealed using heat sealing, stitching, or zipper closure.

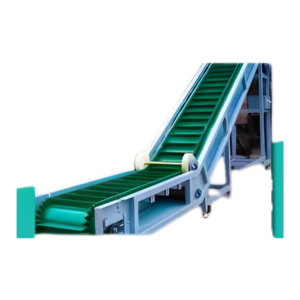

5️⃣ Labeling & Printing (Optional) – Some models allow batch printing or barcode labeling.

6️⃣ Final Output & Conveyor Transport – The filled and sealed bags are moved for storage or distribution.

This fully automated system ensures fast, reliable, and contamination-free packaging.

Applications of Automatic Bag Filling and Sealing Machine

🚜 Agriculture & Fertilizers

- Packaging of seeds, grains, and fertilizers.

🍚 Food Processing Industry

- Ideal for flour, rice, sugar, coffee, spices, and dry fruits.

💊 Pharmaceutical & Chemical Industry

- Ensures safe packaging of powdered chemicals, medicinal powders, and supplements.

🏗 Cement & Construction Materials

- Used for filling cement, sand, and construction aggregates.

🐾 Animal Feed & Pet Food

- Bulk packaging of cattle feed, poultry feed, and pet food.

This multi-industry compatibility makes it a versatile and essential tool in modern packaging lines.

Benefits of Using an Automatic Bag Filling and Sealing Machine

✅ 1. Increases Production Speed

- Automates filling and sealing for faster output.

✅ 2. Ensures Accurate Weighing

- Prevents overfilling or underfilling, reducing material loss.

✅ 3. Minimizes Labor Costs

- Reduces dependency on manual labor, leading to higher efficiency.

✅ 4. Enhances Product Shelf Life

- Air-tight sealing prevents contamination, ensuring product freshness.

✅ 5. Offers Versatile Packaging Options

- Supports various bag types (paper, plastic, woven, and laminated bags).

✅ 6. Reduces Material Waste

- Precise dispensing prevents unnecessary wastage.

✅ 7. Improves Workplace Safety

- Reduces manual handling risks and ensures a safer work environment.

Choosing the Right Automatic Bag Filling and Sealing Machine

When selecting the best bag filling and sealing machine for your business, consider:

✔ Material Type – Does your product include powders, granules, or liquids?

✔ Bag Type & Size – What type of bags and weight range do you need?

✔ Speed & Capacity – How much output do you require per hour?

✔ Sealing Method – Heat sealing, stitching, or zip lock closure?

✔ Automation Level – Fully automatic or semi-automatic?

At Stitch Expert India, we provide customized solutions based on your packaging needs.

Maintenance Tips for an Automatic Bag Filling and Sealing Machine

🛠 Regular Cleaning – Prevents clogging and maintains hygiene.

🛠 Lubricate Moving Parts – Reduces friction and wear.

🛠 Check Sealing Mechanism – Ensures proper sealing and no leakage.

🛠 Inspect Electrical Components – Keeps sensors and controls functioning optimally.

🛠 Schedule Routine Maintenance – Avoids unexpected breakdowns.

Proper maintenance helps extend machine life and ensures uninterrupted operation.

Why Choose Stitch Expert India?

At Stitch Expert India, we specialize in manufacturing top-quality automatic bag filling and sealing machines designed for high-speed, precision, and efficiency.

✔ High-Performance Packaging Solutions

✔ Custom-Built Machines for Various Industries

✔ Competitive Pricing & Cost-Effective Operations

✔ Expert Technical Support & After-Sales Service

✔ Energy-Efficient & Eco-Friendly Designs

📞 Contact us today for a custom quote and boost your packaging efficiency! 🚀

Conclusion

An automatic bag filling and sealing machine is a game-changer in industries that require fast, precise, and contamination-free packaging. Whether you’re in food, agriculture, pharmaceuticals, or construction, this advanced solution enhances efficiency, reduces labor dependency, and improves product quality.

At Stitch Expert India, we offer high-performance, customizable bag filling and sealing machines to meet your specific industry needs.