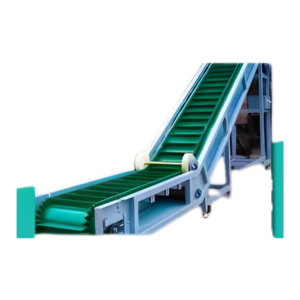

Flat Belt Conveyor

Flat Belt Conveyor

flat belt conveyor designed for industrial efficiency and durability. Suitable for various applications, ensuring optimal performance and reliability.

Send An Enquiry!

Additional Information:

Flat Belt Conveyor: Enhancing Industrial Efficiency and Durability

In today’s fast-paced industrial landscape, efficient material handling systems are paramount to maintaining productivity and ensuring seamless operations. Among the various conveyor systems available, the flat belt conveyor stands out as a versatile and reliable solution, designed to meet the rigorous demands of modern industries. This comprehensive guide delves into the intricacies of flat belt conveyors, exploring their design, applications, benefits, and considerations for selection.

Understanding Flat Belt Conveyors

A flat belt conveyor is a type of conveyor system that utilizes a continuous flat belt to transport materials from one point to another. The belt is typically made from materials such as rubber, synthetic composites, or leather, chosen based on the specific requirements of the application. The belt is looped over pulleys at either end of the conveyor, with one or more powered pulleys driving the belt and moving the materials placed on it. This simple yet effective design makes flat belt conveyors ideal for transporting light to medium-weight loads across various industries.

Key Components and Design Features

-

Belt Material: The choice of belt material is crucial, as it determines the conveyor’s durability, flexibility, and suitability for specific applications. Common materials include:

-

Rubber: Known for its durability and resistance to wear and tear, making it suitable for heavy-duty applications.

-

Synthetic Composites: Materials like PVC or polyurethane offer flexibility and are often used in food processing due to their hygienic properties.

-

Leather: Traditionally used in certain industries, though less common in modern applications.

-

-

Pulleys: These are essential components that support and drive the belt. The drive pulley is powered, propelling the belt forward, while the idler pulley guides and maintains tension.

-

Frame: Constructed from materials like stainless steel or aluminum, the frame provides structural support and can be customized to fit specific operational environments.

-

Motor: Powers the drive pulley, with specifications varying based on load requirements and conveyor length.

-

Support System: Rollers or a slider bed support the belt and the materials being transported, ensuring smooth movement and reducing friction.

Applications of Flat Belt Conveyors

Flat belt conveyors are renowned for their versatility and are employed across a multitude of industries:

-

Manufacturing: Used to transport raw materials, components, and finished products between workstations, assembly lines, and storage areas.

-

Food Processing: Ideal for moving food items through various stages of processing, packaging, and distribution, especially when equipped with food-grade belts.

-

Pharmaceuticals: Ensure the safe and hygienic transfer of medicinal products, maintaining compliance with stringent industry standards.

-

Logistics and Warehousing: Facilitate the efficient movement of packages, parcels, and goods within distribution centers, optimizing order fulfillment processes.

-

Automotive: Assist in the assembly process by conveying parts and components to different stations along the production line.

Advantages of Flat Belt Conveyors

The widespread adoption of flat belt conveyors can be attributed to several key advantages:

-

Versatility: Capable of handling a wide range of products, varying in size, shape, and weight, making them suitable for diverse applications.

-

Cost-Effectiveness: Generally more affordable compared to other conveyor types, both in terms of initial investment and maintenance costs.

-

Smooth Operation: Provide a continuous and stable surface for material transport, minimizing the risk of product damage.

-

Customizability: Easily tailored to specific operational requirements, including adjustable speeds, incline or decline angles, and integration with other equipment.

-

Energy Efficiency: Modern designs focus on reducing energy consumption, contributing to overall operational sustainability.

Considerations for Selecting a Flat Belt Conveyor

When choosing a flat belt conveyor for your operation, several factors should be taken into account to ensure optimal performance:

-

Load Characteristics: Assess the weight, size, and nature of the materials to be conveyed to determine the appropriate belt material and strength.

-

Operational Environment: Consider environmental factors such as temperature, humidity, and exposure to chemicals, which may influence the choice of belt material and conveyor design.

-

Speed Requirements: Align the conveyor’s speed capabilities with the production demands to maintain workflow efficiency.

-

Maintenance Needs: Opt for designs that facilitate easy cleaning and maintenance, especially in industries with strict hygiene standards.

-

Integration: Ensure compatibility with existing systems and equipment to streamline operations and reduce potential bottlenecks.

Maintenance and Best Practices

To maximize the lifespan and efficiency of flat belt conveyors, regular maintenance and adherence to best practices are essential:

-

Routine Inspections: Regularly check for signs of wear, misalignment, or damage to the belt and other components.

-

Proper Tensioning: Maintain appropriate belt tension to prevent slippage or excessive wear.

-

Cleaning: Keep the belt and surrounding areas clean to prevent the accumulation of debris that could interfere with operation.

-

Lubrication: Ensure moving parts are adequately lubricated to reduce friction and wear.

-

Training: Provide operators with proper training on conveyor use and safety protocols to prevent accidents and equipment misuse.

Innovations and Future Trends

The evolution of flat belt conveyors continues as industries seek more efficient and intelligent material handling solutions:

-

Automation Integration: Modern conveyors are increasingly integrated with automated systems, including robotics and advanced sensors, to enhance precision and reduce manual intervention.

-

Smart Conveyors: Equipped with IoT (Internet of Things) capabilities, these conveyors can monitor performance metrics in real-time, predict maintenance needs, and optimize operations.

-

Energy Efficiency: Advances in motor technology and conveyor design are leading to more energy-efficient systems, aligning with global sustainability goals.

-

Modular Designs: The development of modular conveyor components allows for flexible system configurations and easy scalability to adapt to changing operational needs.

Conclusion

Flat belt conveyors play a pivotal role in modern industrial operations, offering a reliable, versatile, and cost-effective solution for material handling needs. By understanding their design features, applications, and maintenance requirements, businesses can optimize their production processes, enhance efficiency, and maintain a competitive edge in their respective industries. As technology advances, flat belt conveyors are set to become even more integral to industrial automation and smart manufacturing practices.