Automatic Bagging Machine

Automatic Bagging Machine

Automatic Bagging Machines provide efficient and high-speed solutions for packaging bulk materials, ensuring precision and productivity in industrial operations.

Send An Enquiry!

Additional Information:

Automatic Bagging Machine – The Ultimate Solution for Efficient Packaging

In modern industrial operations, efficiency, speed, and precision are crucial factors that determine productivity and profitability. An automatic bagging machine is an essential piece of equipment that helps businesses streamline their packaging processes by providing fast, accurate, and automated bagging solutions.

Whether you are handling grains, powders, fertilizers, chemicals, or construction materials, an automatic bagging ensures uniform packaging, minimal wastage, and high output, making it a must-have solution for industrial packaging.

What is an Automatic Bagging Machine?

An automatic bagging is a high-speed packaging system designed to automatically fill and seal bags with bulk materials. Unlike manual or semi-automatic bagging systems, these machines offer fully automated operation, reducing labor costs, human error, and packaging inconsistencies.

These machines work seamlessly in various industries, including agriculture, food processing, pharmaceuticals, chemicals, and construction, ensuring that products are bagged with accuracy and efficiency.

Industries That Use Automatic Bagging Machines

An automatic bagging is widely used in industries that require bulk packaging with precision and consistency:

✔ Agriculture & Farming – For bagging grains, seeds, animal feed, and fertilizers.

✔ Food Processing – Used in packaging flour, sugar, rice, pulses, and powdered food products.

✔ Pharmaceuticals & Chemicals – Ensures contamination-free packaging of powders, granules, and chemicals.

✔ Construction & Cement – Ideal for sand, cement, concrete mix, and dry mortar.

✔ Mining & Minerals – Used for coal, minerals, and industrial raw materials.

With customizable designs and automated controls, automatic bagging machines cater to a wide range of industries, helping them improve efficiency and reduce operational costs.

How Does an Automatic Bagging Machine Work?

An automatic bagging functions through a series of precise and automated steps:

1️⃣ Bag Placement – The machine automatically picks and positions an empty bag at the filling station.

2️⃣ Material Filling – The bulk material is dispensed into the bag using weighing and dosing mechanisms for accurate filling.

3️⃣ Bag Sealing – Once filled, the bag is sealed using heat sealing, stitching, or gluing techniques.

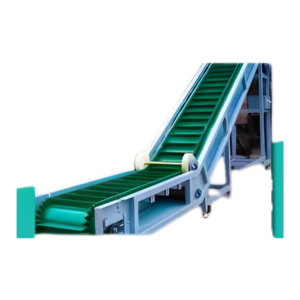

4️⃣ Bag Discharge & Stacking – The sealed bags are then moved along a conveyor for stacking, palletizing, or further processing.

With advanced automation, real-time monitoring, and precise weight control, an automatic bagging machine ensures consistent, reliable, and high-quality packaging output.

Types of Automatic Bagging Machines

There are different types of automatic bagging , each designed for specific applications and materials:

1. Open Mouth Bagging Machine

✅ Best for granules, powders, and free-flowing materials.

✅ Used in agriculture, food, and chemical industries.

2. Valve Bagging Machine

✅ Designed for fine powders like cement, flour, and chemicals.

✅ Ensures dust-free and airtight packaging.

3. FFS (Form, Fill & Seal) Bagging Machine

✅ Forms bags from plastic film, fills, and seals them in one process.

✅ Ideal for high-speed, high-volume packaging operations.

4. Bulk Bag Filling (FIBC Bagging Machine)

✅ Used for large-scale industrial bulk packaging.

✅ Suitable for minerals, fertilizers, and construction materials.

Each of these automatic bagging machine types caters to specific material handling needs, ensuring optimized productivity and cost savings.

Key Features of an Automatic Bagging Machine

✔ Fully Automated Operation – Reduces manual labor and speeds up packaging.

✔ Precision Weighing System – Ensures accurate filling, reducing material wastage.

✔ High-Speed Performance – Capable of bagging thousands of units per hour.

✔ Versatile Material Compatibility – Handles powders, granules, pellets, and bulk materials.

✔ Customizable Bag Sizes & Types – Works with woven, plastic, paper, and laminated bags.

✔ User-Friendly Interface – Equipped with digital controls for easy operation.

✔ Low Maintenance & Durable Build – Designed for continuous industrial use.

With these features, an automatic bagging machine becomes an indispensable asset for industries aiming for efficiency, accuracy, and high-speed packaging.

Benefits of Using an Automatic Bagging Machine

✅ 1. Increased Productivity & Efficiency

- Automates the entire bagging process, improving production rates.

- Reduces downtime and increases output.

✅ 2. Precision & Accuracy in Bagging

- Ensures uniform weight and fill levels, preventing overfilling or underfilling.

- Weighing sensors and digital controls maintain consistency.

✅ 3. Labor & Cost Savings

- Eliminates the need for manual labor, reducing operational costs.

- Improves workplace efficiency with minimal supervision.

✅ 4. Hygienic & Contamination-Free Packaging

- Essential for food, pharmaceutical, and chemical industries.

- Prevents product contamination, leakage, and spillage.

✅ 5. Adaptability & Customization

- Works with various bag sizes, materials, and sealing methods.

- Customizable based on industry-specific requirements.

✅ 6. Enhanced Safety & Reduced Wastage

- Eliminates manual handling errors, reducing injuries and material loss.

- Improves workflow safety and efficiency.

By incorporating an automatic bagging machine into your production line, you can significantly improve operational performance and profitability.

How to Choose the Right Automatic Bagging Machine

When selecting an automatic bagging, consider:

✔ Type of Material – Fine powders, granules, or bulk solids?

✔ Bagging Speed – Low, medium, or high-speed production?

✔ Bag Type & Size – Open-mouth, valve, or FFS bags?

✔ Weighing & Accuracy Requirements – Precision levels needed?

✔ Integration with Existing Systems – Compatibility with conveyors, palletizers, etc.?

At stitch experts, we offer custom-engineered automatic bagging that meet your specific production needs.

Why Choose stitch experts for Your Automatic Bagging Machine?

At stitch experts, we provide:

🔹 High-Quality, Precision-Engineered Automatic Bagging Machines.

🔹 Custom Solutions for Various Industries – Food, Agriculture, Chemicals, and more.

🔹 Cutting-Edge Automation Technology – Ensuring efficiency and cost savings.

🔹 Expert Consultation & After-Sales Support – Helping you optimize your packaging operations.

📞 Contact us today to find the best automatic bagging machine for your industry! 🚀

Conclusion

An automatic bagging machine is a game-changer for industrial packaging, offering speed, accuracy, and cost-efficiency. Whether you are in agriculture, food processing, pharmaceuticals, or construction, investing in an automated bagging system ensures seamless packaging, reduced labor costs, and increased productivity.

At stitch experts, we specialize in providing custom, high-performance automatic bagging solutions.

📞 Get in touch today for a free consultation and pricing details!