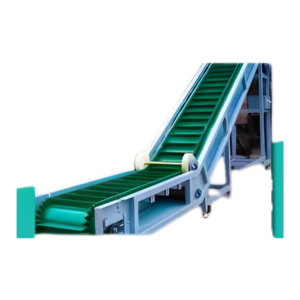

Bag Stackers Conveyors

Bag Stackers Conveyors

Bag Stackers Conveyors are designed to simplify stacking operations in warehouses and agricultural facilities, ensuring efficiency and reduced manual effort.

Send An Enquiry!

Additional Information:

Bag Stacker Conveyor – The Ultimate Solution for Efficient Stacking Operations

In industries where bulk material handling is a daily task, optimizing bag stacking operations is crucial for productivity, efficiency, and cost reduction. A Bag Stacker Conveyor is designed to automate and streamline the stacking process, ensuring smooth material flow, minimal manual effort, and improved workplace safety.

Whether used in warehouses, agricultural facilities, cement plants, or logistics hubs, a high-performance bag stacker conveyor significantly enhances operational efficiency by reducing labor dependency and improving stacking precision.

What is a Bag Stacker Conveyor?

A Bag Stacker Conveyor is an advanced material handling solution that helps in lifting, transporting, and stacking bags in a systematic and efficient manner. Designed to handle heavy loads, this conveyor system simplifies manual stacking operations, making it an ideal choice for industries requiring bulk material storage.

It is widely used in:

✔ Agriculture & Farming – Stacking bags of grains, seeds, fertilizers, and animal feed.

✔ Food Processing Industry – Managing bags of flour, sugar, rice, pulses, and spices.

✔ Cement & Construction – Stacking cement, sand, and construction materials.

✔ Logistics & Warehousing – Optimizing storage and movement of packaged goods.

✔ Chemical & Fertilizer Industry – Organizing bags of chemicals, powders, and fertilizers.

This industrial stacking solution is essential for any facility that handles bulk materials and requires a faster, safer, and more organized stacking process.

Key Features of a Bag Stacker Conveyor

✔ Automated Bag Stacking – Reduces manual labor and speeds up the process.

✔ Adjustable Height & Angle – Allows customizable stacking configurations for different storage needs.

✔ Heavy-Duty Conveyor Belt – Ensures smooth and reliable movement of bags.

✔ Mobile & Easy to Operate – Can be moved and positioned as required.

✔ Energy-Efficient Design – Consumes minimal power while maximizing output.

✔ Durable & Robust Construction – Built with high-quality materials for long-lasting performance.

✔ Customizable Conveyor Length & Width – Suitable for various industries and bag sizes.

✔ Safe & User-Friendly Controls – Designed for easy operation and enhanced safety.

This highly efficient stacking system ensures organized and streamlined material handling, making it a must-have for businesses dealing with bulk bag storage.

How Does a Bag Stacker Conveyor Work?

A bag stacker conveyor operates through a simple yet highly effective mechanism:

Step 1: Bags are Placed on the Conveyor Belt

- Bags are manually or automatically placed on the moving conveyor belt.

Step 2: Bags are Transported to the Stacking Area

- The conveyor moves the bags towards the stacking location, reducing manual lifting efforts.

Step 3: Adjustable Height Ensures Efficient Stacking

- The height-adjustable feature allows the conveyor to raise or lower bags based on the stacking requirement.

Step 4: Bags are Arranged Systematically

- Bags are stacked neatly and efficiently, reducing the risk of product damage or disorganization.

Step 5: Stacked Bags are Ready for Storage or Transport

- Once stacked, the bags are secured and ready for storage, further handling, or transportation.

By automating manual stacking operations, this system ensures quicker, safer, and more efficient bag stacking.

Industries That Benefit from a Bag Stacker Conveyor

🏭 Agriculture & Farming

- Used for stacking fertilizer, grain, seed, and feed bags.

🍚 Food & Beverage

- Ideal for managing bags of flour, sugar, pulses, and rice.

🏗 Cement & Construction

- Perfect for stacking cement, sand, and construction materials.

📦 Logistics & Warehousing

- Streamlines packaged goods stacking and storage.

🔬 Chemical & Pharmaceutical Industry

- Helps in organizing chemical and fertilizer bags efficiently.

This machine is an essential tool for industries that handle bulk bags and require a fast, efficient stacking process.

Benefits of Using a Bag Stacker Conveyor

✅ 1. Improves Efficiency & Productivity

- Automates the stacking process, reducing time and effort.

✅ 2. Reduces Manual Labor Costs

- Eliminates excess manpower, lowering operational expenses.

✅ 3. Enhances Workplace Safety

- Minimizes heavy lifting risks, preventing injuries.

✅ 4. Saves Storage Space

- Enables neater, more compact stacking, maximizing warehouse space.

✅ 5. Handles Heavy Loads with Ease

- Designed for high-volume bag handling without operational strain.

✅ 6. Customizable for Various Applications

- Adjustable height, angle, and speed to meet different industrial needs.

✅ 7. Reduces Product Damage & Wastage

- Ensures careful and precise stacking, preventing bag tears or spills.

✅ 8. Long-Lasting & Low Maintenance

- Built for durability and minimal maintenance requirements.

By investing in a bag stacker conveyor, businesses can increase output, reduce costs, and optimize material handling operations.

How to Choose the Right Bag Stacker Conveyor?

When selecting a bag stacker conveyor, consider these important factors:

✔ Bag Size & Weight Capacity – Ensure it meets your specific bag stacking needs.

✔ Adjustable Height & Inclination – Allows custom stacking configurations.

✔ Belt Material & Durability – Must be strong enough for continuous use.

✔ Mobility & Portability – Should be easy to move and position.

✔ Conveyor Length & Speed – Choose a model that fits your production rate.

✔ Energy Efficiency – Opt for a power-saving design to reduce costs.

At Stitch Experts, we offer customizable bag stacker conveyors to fit your industrial needs.

Maintenance Tips for Optimal Performance

🔧 Regularly Check the Belt & Rollers – Ensures smooth movement and prevents wear.

🔧 Lubricate Moving Parts – Keeps the system running efficiently.

🔧 Inspect Electrical Components – Prevents unexpected breakdowns.

🔧 Clean the System Frequently – Avoids dust buildup and operational issues.

🔧 Perform Routine Safety Checks – Ensures long-lasting and trouble-free performance.

By following proper maintenance guidelines, your bag stacker conveyor will deliver years of reliable performance.

Why Choose Stitch Experts for Bag Stacker Conveyors?

At Stitch Experts, we specialize in high-quality, industry-leading bag stacker conveyors designed for efficiency and durability.

✔ Advanced Engineering & Reliable Performance

✔ Customizable Conveyor Solutions

✔ Energy-Efficient & Cost-Effective Designs

✔ Exceptional After-Sales Support & Maintenance

✔ Trusted by Leading Industries Worldwide

📞 Contact us today and get the best bag stacker conveyor for your business needs! 🚀

Conclusion

A Bag Stacker Conveyor is a game-changer for industries looking to improve efficiency, reduce manual labor, and enhance stacking accuracy. By automating the process, it saves time, reduces costs, and increases overall productivity.

At Stitch Experts, we offer top-quality bag stacker conveyors to help you streamline operations and boost efficiency.

📞 Get in touch today and optimize your material handling process! 🚀