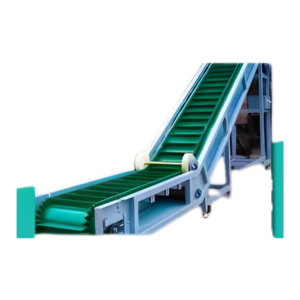

Roller Belt Conveyor

Roller Belt Conveyor

Roller Belt Conveyors offer smooth and efficient material handling for various industries, ensuring precision in transporting goods across production lines.

Send An Enquiry!

Additional Information:

Understanding Belt Conveyor Roller Types – The Backbone of Efficient Material Handling

In modern industries, material handling is a crucial aspect of operational efficiency. Whether it’s manufacturing, warehousing, or logistics, businesses require reliable conveyor systems to streamline production and transportation processes. One of the most efficient solutions is the Roller Belt Conveyor, designed to facilitate smooth and controlled movement of goods.

But what truly defines the efficiency of a roller belt conveyor? The answer lies in the belt conveyor roller types used in its construction.

What is a Roller Belt Conveyor?

A belt conveyor roller types is a specialized conveyor system that integrates rollers beneath the conveyor belt to reduce friction and enhance movement efficiency. This system is ideal for handling lightweight to heavy-duty materials across different industries.

Applications of Roller Belt Conveyors:

🔹 Manufacturing & Production Lines – Ensures smooth movement of raw materials and finished goods.

🔹 Warehousing & Distribution Centers – Enhances storage and order fulfillment operations.

🔹 E-commerce & Retail Logistics – Streamlines the movement of packaged goods.

🔹 Food & Beverage Industry – Supports hygienic and controlled transportation.

🔹 Mining & Heavy Industries – Handles bulk materials efficiently.

By integrating the right belt conveyor roller types, businesses can significantly improve their product handling efficiency and reduce operational costs.

Types of Belt Conveyor Rollers

Understanding the different belt conveyor roller types used in belt conveyors is essential for selecting the right conveyor system for your needs. Each roller type serves a unique function, contributing to the overall performance and longevity of the conveyor.

1. Gravity Rollers

✅ Used for manual or non-powered conveyors.

✅ Ideal for low-friction movement of goods.

✅ Commonly found in warehouse and distribution applications.

2. Drive Rollers

✅ Connected to the motorized drive system.

✅ Provides power and motion to the conveyor belt.

✅ Used in automated conveyor systems.

3. Impact Rollers

✅ Placed at loading points to absorb heavy impact.

✅ Prevents belt damage due to heavy material loading.

✅ Common in mining and bulk material handling.

4. Return Rollers

✅ Supports the return section of the conveyor belt.

✅ Ensures belt alignment and stability.

✅ Reduces wear and tear on the belt.

5. Troughing Rollers

✅ Positioned at various angles to form a trough shape.

✅ Helps in handling loose or bulk materials.

✅ Used in agriculture, construction, and mining industries.

6. Guide Rollers

✅ Prevents belt misalignment and sideways movement.

✅ Ensures smooth belt tracking and operational stability.

✅ Found in curved and high-speed conveyors.

By choosing the belt conveyor roller types , businesses can optimize their material transport process, ensuring efficiency and longevity in their conveyor system.

Key Features of a Roller Belt Conveyor

✔ Smooth & Efficient Material Transport – Reduces manual labor efforts.

✔ Multiple Roller Options for Customization – Ensures optimized performance based on material type.

✔ Durable & Sturdy Construction – Built to withstand heavy loads and continuous operation.

✔ Energy-Efficient Design – Reduces power consumption and operational costs.

✔ Low Maintenance Requirements – Enhances lifespan and reduces downtime.

✔ Customizable for Various Industries – Available in different sizes, speeds, and configurations.

Investing in a high-quality roller belt conveyor ensures seamless, reliable, and cost-effective material handling operations.

Benefits of Using a Roller Belt Conveyor

✅ 1. Enhances Efficiency & Productivity

- Ensures continuous material flow, reducing bottlenecks in operations.

✅ 2. Reduces Wear & Tear on Conveyor Belts

- Roller support minimizes friction, extending belt longevity.

✅ 3. Cost-Effective & Low Maintenance

- Requires minimal lubrication and upkeep, reducing operational expenses.

✅ 4. Handles a Wide Range of Materials

- Can transport lightweight cartons, fragile goods, and heavy industrial materials.

✅ 5. Customizable to Business Needs

- Available in various configurations, roller types, and sizes.

✅ 6. Reduces Manual Labor & Safety Risks

- Automated movement reduces strain on workers, preventing injuries.

A belt conveyor roller types is a smart investment for any industry looking to optimize material flow and efficiency.

Choosing the Right Belt Conveyor Roller Types for Your Business

When selecting a belt conveyor roller types, consider the following:

✔ Material Type & Load Capacity – Determine the weight and type of goods being transported.

✔ Roller Diameter & Spacing – Ensure optimal roller placement for smooth operation.

✔ Conveyor Speed & Length – Match conveyor dimensions to your business requirements.

✔ Industry-Specific Needs – Select rollers suited for heavy-duty, hygienic, or inclined transport applications.

At stitch experts, we provide customized roller belt conveyors designed to meet your industry’s specific needs.

Maintenance Tips for Roller Belt Conveyors

🔧 Regular Roller & Belt Inspections – Prevents misalignment and breakdowns.

🔧 Lubricate Bearings & Moving Parts – Ensures smooth operation and longevity.

🔧 Check for Roller Wear & Tear – Replace damaged rollers to prevent conveyor issues.

🔧 Keep the Conveyor Clean – Avoids dust buildup and operational slowdowns.

Following these best practices ensures that your conveyor system runs smoothly for years to come.

Why Choose for Your Roller Belt Conveyor?

At stitch experts, we specialize in manufacturing high-performance roller belt conveyors tailored to your industry needs.

🔹 Custom Design & Engineering – Built to match your specific application.

🔹 Premium-Quality Rollers & Components – Ensures durability and efficiency.

🔹 Energy-Efficient & Cost-Effective Solutions – Reduces operational costs.

🔹 Expert Support & Maintenance Services – Keeps your system running optimally.

🔹 Trusted by Leading Industries Worldwide – Backed by a reputation of reliability.

📞 Get in touch with us today to find the belt conveyor roller types for your business! 🚀

Conclusion

A roller belt conveyor is an essential tool for businesses looking to optimize material handling operations. By understanding the different belt conveyor roller types, you can select the right system that meets your needs, improves efficiency, and reduces operational costs.

At stitch experts, we offer custom conveyor solutions built for performance, durability, and reliability.

📞 Contact us today and take your material handling efficiency to the next level! 🚀