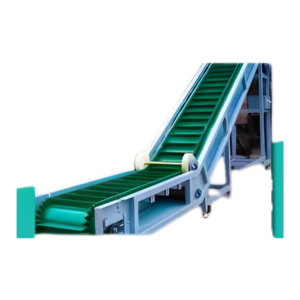

Loading Conveyor Systems

Loading Conveyor Systems

Loading Conveyor Systems streamline material handling during loading and unloading processes, ensuring efficiency and reducing manual effort in warehouses and logistics centers.

Send An Enquiry!

Additional Information:

Conveyor Loading System – The Ultimate Solution for Efficient Material Handling

In today’s fast-paced industries, efficient material handling plays a critical role in optimizing workflow, reducing labor costs, and ensuring seamless logistics operations. A Conveyor Loading System is an essential tool designed to streamline the loading and unloading process, making it faster, safer, and more efficient.

Whether you’re operating a warehouse, distribution center, manufacturing unit, or logistics hub, investing in a high-quality loading conveyor system can significantly enhance your productivity while minimizing manual labor.

What is a Conveyor Loading System?

A Conveyor Loading System is a specialized conveyor solution designed to automate the loading and unloading of goods. It efficiently transports boxes, parcels, bags, and bulk materials from one point to another, reducing the need for excessive manual handling.

Applications of a Loading Conveyor System:

🔹 Warehouses & Distribution Centers – Simplifies material transfer and order fulfillment.

🔹 E-commerce & Retail – Speeds up parcel movement for faster deliveries.

🔹 Manufacturing Units – Optimizes workflow efficiency for raw materials and finished goods.

🔹 Logistics & Freight Handling – Ensures faster loading and unloading of trucks and containers.

🔹 Agriculture & Food Processing – Facilitates the movement of bulk materials like grains, flour, and packaged goods.

This automated material handling solution significantly boosts efficiency while minimizing operational costs and workplace injuries.

Key Features of a Conveyor Loading System

✅ Automated Material Movement – Reduces manual effort and increases efficiency.

✅ High Load-Bearing Capacity – Handles heavy loads with ease.

✅ Adjustable Height & Length – Suitable for different loading and unloading applications.

✅ Mobile & Flexible Design – Easy to relocate for versatile operations.

✅ Durable & Sturdy Construction – Built to withstand heavy-duty industrial use.

✅ Smooth & Controlled Speed – Ensures safe and efficient material transport.

✅ Customizable for Various Industries – Designed to meet specific business needs.

✅ Energy-Efficient Operation – Reduces power consumption while maximizing productivity.

By integrating these advanced features, a conveyor loading system ensures that your material handling operations remain smooth, efficient, and cost-effective.

How Does a Conveyor Loading System Work?

A loading conveyor system operates using a series of belts or rollers that transport goods from one point to another. The working process involves:

Step 1: Loading Goods onto the Conveyor

- Items such as boxes, bags, or bulk materials are placed on the moving conveyor belt.

Step 2: Efficient Transport Mechanism

- The conveyor moves the goods towards the designated area, ensuring minimal manual effort.

Step 3: Adjustable Height & Incline for Optimized Transfer

- The conveyor can be adjusted in height and angle to match the loading or unloading requirements.

Step 4: Smooth Discharge of Goods

- Items are transferred to the next phase, whether into trucks, containers, storage racks, or processing units.

By automating these steps, loading conveyor systems eliminate manual inefficiencies, resulting in faster, safer, and more organized operations.

Industries That Benefit from a Conveyor Loading System

🏭 Warehousing & Distribution

- Streamlines the handling of goods for shipping, receiving, and order fulfillment.

🚚 Logistics & Freight Transport

- Enhances the loading and unloading efficiency of trucks, containers, and cargo holds.

🛒 E-commerce & Retail

- Facilitates rapid package movement for faster deliveries.

🏗 Manufacturing & Industrial Production

- Ensures seamless transfer of raw materials and finished products.

🌾 Agriculture & Food Industry

- Helps in bulk handling of grains, flour, packaged foods, and beverages.

By adopting a high-performance conveyor loading system, businesses in these industries can experience faster operations, reduced costs, and enhanced productivity.

Benefits of Using a Conveyor Loading System

✅ 1. Enhances Efficiency & Productivity

- Reduces manual labor efforts, ensuring faster loading and unloading times.

✅ 2. Minimizes Manual Handling Risks

- Helps prevent workplace injuries caused by lifting heavy materials.

✅ 3. Saves Time & Labor Costs

- Speeds up operations, reducing the need for excessive manpower.

✅ 4. Improves Warehouse Organization

- Ensures structured material handling for a more organized workspace.

✅ 5. Reduces Product Damage

- Minimizes human handling errors, keeping items safe and intact.

✅ 6. Customizable for Various Needs

- Available in different sizes, lengths, and load capacities.

✅ 7. Mobile & Space-Saving Design

- Can be moved and stored easily, making it ideal for dynamic environments.

✅ 8. Cost-Effective Long-Term Investment

- Reduces operational expenses, providing higher ROI.

A well-designed conveyor loading system makes material movement seamless, efficient, and cost-effective, offering significant advantages for businesses.

Choosing the Right Conveyor Loading System for Your Business

When selecting a loading conveyor system, consider the following factors:

✔ Material Type & Load Capacity – Ensure the system is built for your specific material handling needs.

✔ Conveyor Length & Speed – Choose the right size and speed settings for optimal workflow.

✔ Adjustable Features – Height and incline adjustment for customized stacking and loading requirements.

✔ Durability & Build Quality – Select a model made from high-quality materials for long-term reliability.

✔ Energy Consumption – Opt for an energy-efficient system to reduce operational costs.

At stitch experts, we offer customized conveyor loading solutions designed to fit your specific business needs.

Maintenance Tips for Maximizing Performance

To keep your loading conveyor system in optimal condition, follow these essential maintenance tips:

🔧 Regular Belt & Roller Inspections – Prevents unexpected breakdowns.

🔧 Lubricate Moving Parts – Ensures smooth and efficient operation.

🔧 Check Electrical Components – Keeps controls and motors functioning properly.

🔧 Clean the System Periodically – Prevents dust accumulation and wear.

🔧 Perform Routine Safety Checks – Ensures long-lasting performance and workplace safety.

By following these maintenance best practices, you can maximize the lifespan and efficiency of your conveyor system.

Why Choose for Your Conveyor Loading System?

At stitch experts, we provide premium quality conveyor loading systems tailored to meet your specific material handling needs.

✔ Customizable Conveyor Solutions

✔ Energy-Efficient & Cost-Effective Designs

✔ Reliable Performance & Durability

✔ Expert Technical Support & Maintenance Services

✔ Trusted by Leading Industries Worldwide

📞 Contact us today to find the best conveyor loading system for your business! 🚀

Conclusion

A Conveyor Loading System is a must-have solution for industries looking to enhance efficiency, reduce manual labor, and optimize material handling. By investing in a high-quality system, businesses can improve productivity, ensure workplace safety, and achieve cost savings.

At Stitch Experts, we specialize in custom conveyor solutions that cater to various industries.