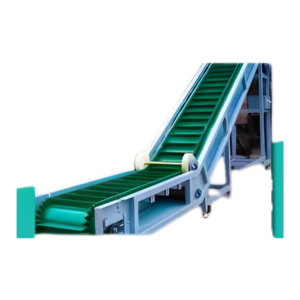

Drag Chain Conveyors

Drag Chain Conveyors

Drag Chain Conveyors are designed for efficient and controlled movement of bulk materials, ensuring reliability in industrial operations.

Send An Enquiry!

Additional Information:

Drag Chain Conveyor – Reliable Solution for Bulk Material Handling

Introduction

Efficient material transport is the backbone of industrial operations, ensuring smooth workflow and improved productivity. A Drag Chain Conveyor is a robust and reliable system designed to move bulk materials efficiently across various industrial setups.

These conveyors are built to handle abrasive, sticky, or heavy-duty materials, making them ideal for industries like agriculture, mining, cement, and chemical processing.

🔹 What is a Drag Chain Conveyor?

A Drag Chain Conveyor is a mechanical system that uses chains and paddles to move bulk materials inside an enclosed casing. It provides precise, controlled, and dust-free transportation of materials such as grains, cement, coal, and other industrial goods.

Let’s explore its features, benefits, and applications in detail.

How Does a Drag Chain Conveyor Work?

The working principle of a Drag Chain Conveyor is simple yet highly efficient:

✅ Step 1: Material Loading

- Bulk materials are fed into the conveyor system through a hopper or inlet.

✅ Step 2: Chain Movement

- The drag chain and paddles move inside an enclosed housing, pulling the materials along the conveyor path.

✅ Step 3: Controlled Discharge

- Materials are gradually discharged at the desired location, ensuring minimal spillage.

This enclosed transport system makes drag chain highly effective for handling dusty or abrasive materials without contamination.

Types of Drag Chain Conveyors

Different types of drag chain are used based on material type and industrial requirements:

1️⃣ En-Masse Chain Conveyor

🔹 Moves bulk materials in a controlled, high-volume flow.

🔹 Best for grains, cement, and chemical industries.

2️⃣ Tubular Chain Conveyor

🔹 Uses a sealed tube with a continuous chain system.

🔹 Ideal for food processing and pharmaceutical applications.

3️⃣ Scraper Chain Conveyor

🔹 Designed for wet, sticky, or fine materials like sludge and ash.

🔹 Ensures consistent flow without clogging.

4️⃣ Twin-Chain Conveyor

🔹 Features dual parallel chains for heavy-duty applications.

🔹 Used in power plants, cement manufacturing, and mining.

Choosing the right type depends on material properties, capacity needs, and operational requirements.

Key Features of Drag Chain Conveyors

✔ Heavy-Duty Construction – Built to handle large volumes of bulk materials.

✔ Fully Enclosed Design – Ensures dust-free and contamination-free material transport.

✔ Low Maintenance – Fewer moving parts lead to reduced wear and tear.

✔ Energy-Efficient Operation – Requires less power than pneumatic or screw conveyors.

✔ Customizable Designs – Available in various sizes, lengths, and chain configurations.

These features make drag chain conveyors a preferred choice for industries requiring efficient and controlled material handling.

Advantages of Using a Drag Chain Conveyor

✅ 1. High Efficiency in Material Handling

- Designed for continuous and controlled transport of bulk materials.

- Handles sticky, abrasive, or heavy-duty loads with ease.

✅ 2. Dust-Free & Contamination-Free Transport

- Fully enclosed casing prevents material leakage and contamination.

- Ideal for industries handling hazardous or sensitive materials.

✅ 3. Reduced Maintenance & Longer Lifespan

- Fewer mechanical components mean lower maintenance costs.

- Durable chains and paddles ensure long operational life.

✅ 4. Versatile Applications Across Industries

- Suitable for mining, agriculture, cement, food processing, and more.

- Works with powders, granules, and large bulk materials.

✅ 5. Space-Saving & Customizable Design

- Horizontal, inclined, or vertical configurations available.

- Can be integrated into existing production lines for optimized space utilization.

These benefits make drag chain conveyors a practical and cost-effective solution for bulk material movement.

Industries That Use Drag Chain Conveyors

🔹 Agriculture & Grain Handling – Transporting grains, fertilizers, and seeds.

🔹 Cement & Construction – Moving cement, limestone, and aggregates.

🔹 Mining & Power Plants – Handling coal, minerals, and ash.

🔹 Chemical & Petrochemical – Safely transferring hazardous chemicals.

🔹 Food Processing – Hygienic transport of ingredients like sugar, flour, and coffee.

These industries depend on drag chain for seamless, dust-free, and efficient material transport.

Choosing the Right Drag Chain Conveyor

When selecting a drag chain, consider:

✔ Material Type & Flow Rate – Lightweight vs. heavy-duty bulk materials.

✔ Conveyor Length & Design – Customizable layouts to fit your space.

✔ Chain & Paddle Material – Corrosion-resistant and durable options available.

✔ Power Consumption & Efficiency – Energy-saving designs for cost-effective operations.

At stitch experts, we specialize in customized conveyor solutions for various industries.

Why Choose for Drag Chain Conveyors?

At stitch experts, we are committed to providing:

✔ Premium-Quality Drag Chain Conveyors for efficient material transport.

✔ Customized Solutions tailored to your industry needs.

✔ Durable & Low-Maintenance Designs to maximize ROI.

✔ Expert Engineering Support & On-Time Delivery.

📞 Contact us today for a custom conveyor system that fits your business!

Conclusion

A Drag Chain Conveyor is an indispensable tool for industries handling bulk materials efficiently and safely. Whether you need a dust-free transport system, heavy-duty material movement, or space-saving conveyor solutions, drag chain offer unmatched reliability and efficiency.

At stitch experts, we provide tailor-made conveyor solutions to enhance your operational productivity.

📞 Get in touch today and revolutionize your bulk material handling process! 🚀