Belt Type Bucket Elevators

Belt Type Bucket Elevators

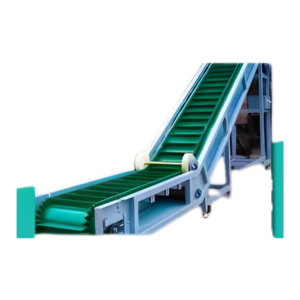

Belt Type Bucket Elevators provide smooth and efficient vertical transportation of materials, ensuring high performance in diverse industrial applications.

Send An Enquiry!

Additional Information:

Industrial Bucket Elevators – Efficient Vertical Material Handling

In industries where bulk materials need to be transported vertically, having a reliable and efficient conveying system is essential. Industrial Bucket Elevators, especially Belt Type Bucket Elevators, offer a smooth and high-performance solution for vertical material movement.

These elevators are widely used in agriculture, construction, food processing, cement, and mining industries, ensuring a continuous and controlled flow of materials with minimal energy consumption.

If you’re looking for a durable, high-capacity, and cost-effective solution for your bulk handling operations, a Belt Type Bucket Elevator is the perfect choice.

What is an Industrial Bucket Elevator?

An industrial bucket elevators is a specialized conveyor system designed for lifting bulk materials in a controlled manner. It consists of buckets attached to a belt, which scoops, lifts, and discharges materials at the desired height.

This system is ideal for moving free-flowing and semi-free-flowing materials like:

✔ Grains & Seeds – Wheat, rice, corn, barley, etc.

✔ Powders & Chemicals – Cement, limestone, fertilizers, etc.

✔ Aggregates & Minerals – Sand, gravel, ores, and crushed stone.

✔ Food Products – Sugar, salt, coffee beans, and more.

By minimizing manual handling and increasing efficiency, Belt Type industrial bucket elevators ensure faster and safer operations.

How Does a Belt Type Bucket Elevator Work?

The industrial bucket elevators operates through a continuous loop system, where the buckets pick up, transport, and discharge materials efficiently.

✅ 1. Material Intake & Pickup

- The elevator picks up bulk materials from a hopper or loading station.

✅ 2. Vertical Lifting

- The buckets are attached to a high-strength belt, moving materials upward to the discharge point.

✅ 3. Discharge & Unloading

- At the top, materials are released via centrifugal or gravity discharge, ensuring smooth unloading.

This automated and continuous process enhances productivity and efficiency in material handling.

Types of Industrial Bucket Elevators

Different industries require different industrial bucket elevators configurations based on material type and operational needs.

1️⃣ Belt Type Bucket Elevator (Most Common & Versatile)

✔ Uses a durable belt with attached buckets.

✔ Ideal for handling light to medium-density materials.

✔ Ensures quiet operation with minimal maintenance.

2️⃣ Chain Type Bucket Elevator

✔ Features heavy-duty chains instead of belts.

✔ Suitable for abrasive and high-temperature materials.

✔ More durable but requires higher maintenance.

3️⃣ Centrifugal Discharge Bucket Elevator

✔ Buckets are spaced apart for rapid material discharge.

✔ Perfect for handling free-flowing bulk materials.

4️⃣ Continuous Discharge Bucket Elevator

✔ Buckets are closely spaced for smooth & gentle unloading.

✔ Used for fragile and sluggish materials.

Choosing the right type depends on your industry, material properties, and operational requirements.

Key Features of a Belt Type Bucket Elevator

✔ Smooth Vertical Transport – Ideal for handling powders, granules, and small aggregates.

✔ High-Strength Belt Design – Ensures durability & long service life.

✔ Energy-Efficient Operation – Consumes low power with maximum output.

✔ Minimal Product Loss – Reduces spillage & dust generation.

✔ Compact Footprint – Saves space while maximizing material transport capacity.

✔ Customizable Configurations – Available in various heights & bucket capacities.

✔ Low Maintenance – Designed for long-term performance with minimal downtime.

With these advanced features, industrial bucket elevators provide superior efficiency and reliability.

Benefits of Using an Industrial Bucket Elevator

✅ 1. Increased Efficiency & Productivity

- Automates vertical material transport, reducing manual labor.

✅ 2. Cost-Effective Operation

- Reduces energy consumption and operational costs.

✅ 3. Improved Safety Standards

- Prevents material spillage & dust pollution, ensuring clean operations.

✅ 4. Versatile Applications

- Can be used in food, agriculture, construction, mining, and chemical industries.

✅ 5. Long-Term Durability

- Corrosion-resistant and wear-resistant components ensure extended service life.

Investing in a industrial bucket elevators enhances operational efficiency, safety, and cost savings.

Industries That Benefit from Belt Type Bucket Elevators

🔹 Food & Agriculture – Used for grains, cereals, and flour.

🔹 Cement & Construction – Handles sand, limestone, and cement.

🔹 Mining & Minerals – Lifts coal, ores, and crushed rock.

🔹 Chemical Processing – Transports fertilizers and industrial powders.

🔹 Recycling & Waste Management – Moves plastic pellets and scrap materials.

No matter the industry, industrial bucket elevators offer efficient and reliable material handling.

How to Choose the Right Belt Type Bucket Elevator?

Before selecting an Industrial Bucket Elevator, consider the following:

✔ Material Type & Density – Choose a system based on powders, granules, or aggregates.

✔ Bucket Size & Speed – Match to your production rate & required capacity.

✔ Belt Strength & Durability – Opt for high-quality materials to ensure longevity.

✔ Discharge Type – Select centrifugal or continuous discharge based on material flow.

✔ Maintenance & Cleaning Requirements – Ensure easy access for servicing & inspection.

Need help selecting the perfect bucket elevator? Our experts can guide you!

Why Choose stitch experts for Industrial Bucket Elevators?

At stitch experts, we provide:

✔ High-Quality Industrial Bucket Elevators – Built for maximum efficiency & durability.

✔ Custom-Designed Solutions – Tailored for your specific material handling needs.

✔ Competitive Pricing – Affordable options without compromising quality.

✔ Reliable After-Sales Support – Installation, maintenance, and troubleshooting services.

📞 Contact us today for a custom quote on Belt Type Bucket Elevators!

Conclusion

An Industrial Bucket Elevator is an essential solution for businesses requiring reliable, efficient, and cost-effective vertical material transport. Whether you are in agriculture, construction, or manufacturing, investing in a Belt Type Bucket Elevator significantly improves productivity and operational efficiency.

At stitch experts, we offer top-of-the-line Belt Type Bucket Elevators customized to meet your business needs.

📞 Get in touch today and take your material handling operations to the next level! 🚀