Jumbo Bag Filling Machine

Jumbo Bag Filling Machine

Jumbo Bag Filling Machine ensures precise and efficient filling of large-capacity bags, optimizing bulk material packaging.

Send An Enquiry!

Additional Information:

Jumbo Bag Filling Machine – Efficient Bulk Material Packaging Solution

In industries that handle bulk materials, efficient and accurate bagging solutions are essential to optimize productivity and reduce material waste. A jumbo bag filling machine is designed to streamline the packaging process by providing precise, fast, and efficient filling of large-capacity bags.

Whether you operate in agriculture, construction, chemical, or food processing industries, this machine ensures maximum efficiency, reduced labor costs, and improved material handling.

Let’s explore its features, benefits, and applications in detail.

What is a Jumbo Bag Filling Machine?

A jumbo bag filling machine, also known as an FIBC (Flexible Intermediate Bulk Container) filling system, is designed to fill large bags (commonly ranging from 500 kg to 2000 kg) with materials such as powders, granules, and other bulk goods.

This machine offers automated and semi-automated filling options, ensuring accurate weight measurement, dust-free operation, and efficient material flow control.

How Does a Jumbo Bag Filling Machine Work?

The filling process follows a structured and automated approach to ensure precision and efficiency:

✅ 1. Bag Positioning & Clamping

- The empty jumbo bag is placed on the filling station.

- The machine’s clamping mechanism holds the bag securely to prevent displacement.

✅ 2. Material Feeding & Weighing

- The system precisely dispenses material into the bag.

- A weighing mechanism ensures exact filling, preventing overfilling or material loss.

✅ 3. Dust-Free & Controlled Filling

- The enclosed design prevents material spillage and airborne dust.

- Adjustable flow control ensures a consistent and smooth filling process.

✅ 4. Bag Release & Sealing

- Once the target weight is reached, the bag is automatically released.

- The filled bag is then sealed or tied securely before being transported.

This streamlined process eliminates manual labor errors, increases filling speed, and enhances workplace safety.

Types of Jumbo Bag Filling Machine

Different filling systems are available to cater to various industry needs:

1️⃣ Gravity-Fed Jumbo Bag Filling Machine

🔹 Uses gravity-based flow for free-flowing materials like grains and powders.

🔹 Best for agriculture and food industries.

2️⃣ Screw Conveyor Jumbo Bag Filling Machine

🔹 Utilizes a screw mechanism for precise material dispensing.

🔹 Ideal for fine powders and chemical industries.

3️⃣ Pneumatic Jumbo Bag Filling Machine

🔹 Uses airflow pressure for lightweight materials like plastic resins.

🔹 Best suited for pharmaceutical and plastic industries.

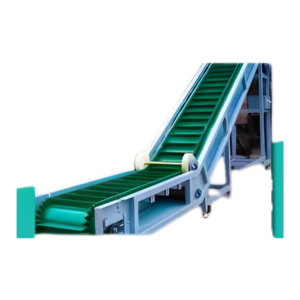

4️⃣ Belt Conveyor Jumbo Bag Filling Machine

🔹 Equipped with a conveyor belt for continuous filling operations.

🔹 Commonly used in cement, mining, and construction.

Each type serves specific materials and industry requirements, ensuring efficient bagging solutions.

Key Features of a Jumbo Bag Filling Machine

✔ High-Speed & Accurate Weighing System – Ensures precise filling without material wastage.

✔ Heavy-Duty Construction – Built with stainless steel or robust metal for long-lasting durability.

✔ Fully Enclosed Design – Prevents material spillage and airborne dust contamination.

✔ Customizable Bag Holding Mechanism – Accommodates various bag sizes and capacities.

✔ User-Friendly Interface – Automated or semi-automated controls for seamless operation.

✔ Low Maintenance & High Efficiency – Reduces downtime and improves overall productivity.

These features make the jumbo bag filling machine a smart investment for businesses handling bulk materials.

Advantages of Using a Jumbo Bag Filling Machine

✅ 1. Increased Efficiency & Productivity

- Automates the filling process, reducing manual labor and time consumption.

- Enhances packaging speed, ensuring faster and more efficient operations.

✅ 2. Precise Weight Measurement & Cost Savings

- The integrated weighing system ensures exact filling, reducing material loss.

- Prevents overfilling and underfilling, optimizing packaging expenses.

✅ 3. Dust-Free & Clean Working Environment

- Sealed filling station prevents dust emissions, maintaining a clean workspace.

- Complies with safety and environmental regulations in industries like chemicals and food.

✅ 4. Versatile Applications Across Multiple Industries

- Suitable for packaging powders, granules, aggregates, and raw materials.

- Used in industries like agriculture, chemicals, cement, and pharmaceuticals.

✅ 5. Reduced Labor Costs & Enhanced Safety

- Eliminates manual handling of heavy bags, reducing workforce fatigue.

- Automated controls improve workplace safety by minimizing direct human contact.

These benefits make the jumbo bag filling machine a highly valuable asset for bulk packaging operations.

Industries That Use Jumbo Bag Filling Machine

🔹 Agriculture & Fertilizer – Filling grains, seeds, and fertilizers.

🔹 Cement & Construction – Bagging cement, sand, and aggregates.

🔹 Mining & Minerals – Transporting coal, ores, and minerals.

🔹 Chemical & Petrochemical – Packaging powdered chemicals and synthetic materials.

🔹 Food Processing – Hygienic filling of sugar, flour, coffee, and other bulk food products.

These industries rely on jumbo bag fillers for optimized bulk material packaging.

Choosing the Right Jumbo Bag Filling Machine

To select the best jumbo bag filling machine for your operations, consider:

✔ Material Type & Flow Rate – Granular, powder, or solid bulk materials.

✔ Bag Size & Weight Capacity – Customizable options for 500 kg – 2000 kg bags.

✔ Automation Level – Manual, semi-automatic, or fully automated.

✔ Space & Layout Requirements – Compact or large-scale industrial setups.

At stitch experts, we offer tailor-made solutions for your specific bulk packaging needs.

Why Choose for Jumbo Bag Filling Machine?

At stitch experts, we specialize in:

✔ High-Performance Jumbo Bag Filling Machines for industrial packaging.

✔ Customizable Solutions tailored to your business requirements.

✔ Durable & Low-Maintenance Equipment to maximize efficiency.

✔ Expert Technical Support & On-Time Delivery.

📞 Contact us today for the best bulk material handling solutions!

Conclusion

A jumbo bag filling machine is an indispensable tool for industries looking to automate and optimize their bulk packaging process. With precision weighing, dust-free filling, and high-speed operations, these machines enhance efficiency, safety, and cost-effectiveness.

At stitch experts, we offer state-of-the-art jumbo bag filling machines to help your business achieve seamless material packaging.

📞 Get in touch today to upgrade your bulk bagging operations! 🚀