Jumbo Bag Filling Machine

Jumbo Bag Filling Machine

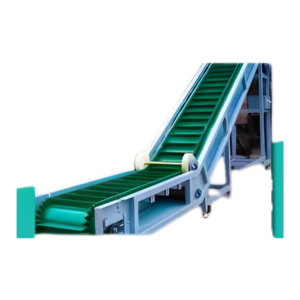

Jumbo Bag Filling Machines are designed for large-scale packaging, providing accurate and efficient filling solutions for bulk materials.

Send An Enquiry!

Additional Information:

Jumbo Bag Filling Machine – Efficient Bulk Material Packaging

Efficient packaging of bulk materials requires precision, speed, and reliability. A jumbo bag filling machine is specifically designed to handle large-scale bagging operations, ensuring accurate and efficient filling of jumbo bags with minimal material loss.

Industries dealing with powders, granules, and bulk commodities such as agriculture, chemicals, construction, and minerals benefit greatly from this automated packaging solution.

What is a Jumbo Bag Filling Machine?

A jumbo bag filling machine is an industrial-grade system used for filling bulk bags (FIBC bags, big bags, or super sacks). It is designed to handle large volumes of materials efficiently, making it an essential solution for industries requiring high-capacity bagging operations.

Key Functions:

✔ Accurately weighs and dispenses bulk materials.

✔ Supports various bag sizes and weights.

✔ Reduces manual labor and material wastage.

✔ Enhances packaging speed and operational efficiency.

Types of Jumbo Bag Filling Machines

1️⃣ Gravity-Fed jumbo bag filling machinee – Ideal for free-flowing materials like grains and plastic pellets.

2️⃣ Screw Conveyor-Based Filling Machine – Best for powders and fine materials requiring controlled feeding.

3️⃣ Pneumatic jumbo bag filling machine – Suitable for dusty and lightweight materials.

4️⃣ Bulk Bag Filling Machine with Weighing System – Ensures precise weight measurement before sealing.

Each type is designed to meet specific industry needs, ensuring optimal performance and accuracy.

How Does a Jumbo Bag Filling Machine Work?

The machine follows a step-by-step process for seamless bagging:

🔹 Step 1: Bag Placement & Inflation

- The operator attaches the empty jumbo bag to the filling spout.

- The machine inflates the bag for proper material distribution.

🔹 Step 2: Material Weighing & Filling

- Bulk materials are dispensed into the bag via gravity, screw conveyor, or pneumatic systems.

- The built-in weighing system ensures precise filling.

🔹 Step 3: Bag Sealing & Discharge

- Once the target weight is reached, the bag is sealed using stitching or heat sealing.

- The filled bag is then moved for storage or transportation.

This automated process improves efficiency while maintaining accuracy and material integrity.

Key Features of Jumbo Bag Filling Machines

✔ High Filling Capacity – Can fill bags weighing 500 kg to 2000 kg.

✔ Accurate Weighing System – Reduces material loss and ensures precise bagging.

✔ Adjustable Bag Sizes – Compatible with various bag dimensions.

✔ Dust Control System – Prevents material spillage and dust contamination.

✔ Heavy-Duty Construction – Built with robust materials for long-term industrial use.

✔ Easy Operation & Maintenance – User-friendly interface with automated controls.

These features make Jumbo bag filling machine a reliable and cost-effective solution for large-scale packaging.

Benefits of Using a Jumbo Bag Filling Machine

✅ 1. Increased Efficiency & Productivity

- Automates the bagging process for faster operations.

- Handles large volumes with minimal manual intervention.

✅ 2. Precision in Bag Filling

- Advanced weighing technology ensures consistent and accurate bagging.

- Prevents overfilling or underfilling, reducing material wastage.

✅ 3. Reduced Labor Costs & Time

- Eliminates the need for manual bag filling.

- Allows fewer operators to handle bulk material packaging.

✅ 4. Improved Workplace Safety

- Reduces exposure to dust, spills, and heavy lifting.

- Ensures safe handling of hazardous or sensitive materials.

✅ 5. Versatile Applications

- Suitable for food, agriculture, chemicals, minerals, and construction materials.

- Works with granules, powders, cement, fertilizers, and more.

With these benefits, investing in a Jumbo Bag Filling Machine ensures higher productivity and cost savings.

Industries That Use Jumbo Bag Filling Machines

🔹 Agriculture & Fertilizers – Filling seeds, grains, and fertilizers.

🔹 Chemical Industry – Bagging of powders, detergents, and industrial chemicals.

🔹 Cement & Construction – Filling cement, sand, and other building materials.

🔹 Mining & Minerals – Handling coal, minerals, and ores.

🔹 Food & Pet Industry – Packaging of flour, sugar, animal feed, and pet food.

This machine ensures safe, clean, and efficient packaging across diverse industries.

How to Choose the Right Jumbo Bag Filling Machine?

When selecting a jumbo bag filling machine, consider the following:

✔ Material Type – Is it a powder, granule, or solid material?

✔ Bag Size & Weight Capacity – Machines can handle bags from 500 kg to 2000 kg.

✔ Filling Speed & Accuracy – Ensure it meets your production requirements.

✔ Sealing & Weighing System – Look for reliable weighing and sealing mechanisms.

✔ Automation Level – Choose between semi-automatic or fully automatic models.

At stitch experts, we offer customized solutions to meet your specific bagging needs.

Why Choose for Jumbo Bag Filling Machine?

At stitch experts, we specialize in high-quality industrial packaging solutions. Our Jumbo Bag Filling Machines offer:

🔹 Cutting-Edge Automation – Ensuring fast and precise bagging.

🔹 Customizable Designs – Tailored to your industry and material needs.

🔹 Heavy-Duty Construction – Built for long-term durability.

🔹 Excellent Customer Support – Providing installation, training, and maintenance.

📞 Get in touch today for a custom quote and expert consultation on selecting the best Jumbo Bag Filling Machine for your business!

Conclusion

A jumbo bag filling machine is an essential solution for industries handling bulk materials. With automated filling, precision weighing, and efficient material handling, these machines enhance productivity, accuracy, and cost efficiency.

At stitch experts, we offer state-of-the-art Jumbo Bag Filling Machines designed to meet your packaging needs.

📞 Contact us today to learn more and get a personalized quote! 🚀