Semi Automatic Bagging Machine

Semi Automatic Bagging Machine

Semi Automatic Bagging Machines offer a cost-effective and efficient solution for packaging operations, combining manual and automated processes for optimal performance.

Send An Enquiry!

Additional Information:

Semi Automatic Bagging Machine – Cost-Effective and Efficient Packaging Solution

In the world of industrial packaging, businesses need a balance of automation, precision, and cost-efficiency. A semi automatic bagging machine is the perfect solution for companies looking to increase productivity while maintaining flexibility in their packaging processes.

Designed to combine manual and automated operations, these machines provide accurate, efficient, and consistent bagging, making them ideal for small to medium-scale industries that require high-quality packaging without the complexity of full automation.

Whether you are packaging grains, powders, chemicals, fertilizers, or food products, a semi automatic bagging machine ensures seamless and reliable performance, reducing labor effort and improving operational efficiency.

What is a Semi Automatic Bagging Machine?

A semi automatic bagging is an industrial packaging system that automates part of the bagging process while still requiring some level of manual operation. Typically, an operator will place an empty bag onto the machine, after which the system automatically fills the bag with a precise amount of material and then moves it to the sealing or stitching station.

This type of machine is ideal for businesses that require speed and accuracy but do not need a fully automated bagging line.

Industries That Use Semi Automatic Bagging Machines

A semi automatic bagging is used in industries that require bulk packaging with precision and flexibility:

✔ Agriculture & Farming – Packaging grains, animal feed, seeds, and fertilizers.

✔ Food Processing – Used for flour, sugar, rice, pulses, and dry food products.

✔ Pharmaceuticals & Chemicals – Ensures safe bagging of powders, granules, and chemical substances.

✔ Construction & Cement – Perfect for bagging cement, sand, dry mortar, and other construction materials.

✔ Mining & Minerals – Used for coal, minerals, and other bulk raw materials.

With versatile applications across multiple industries, a semi automatic bagging machine is a cost-effective way to improve efficiency while maintaining control over the packaging process.

How Does a Semi Automatic Bagging Machine Work?

A semi automatic bagging machine operates through a combination of manual handling and automated processes:

1️⃣ Bag Placement – The operator manually places an empty bag onto the filling station.

2️⃣ Material Filling – The machine automatically dispenses the material using a precise weighing system.

3️⃣ Bag Removal – Once filled, the operator removes the bag and moves it to the sealing station.

4️⃣ Bag Sealing – The bag is sealed using stitching, heat sealing, or glue sealing.

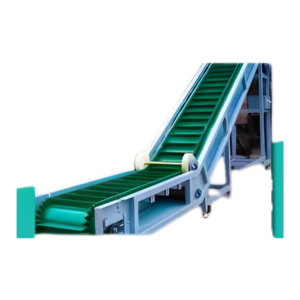

5️⃣ Bag Stacking or Transportation – The sealed bags are either stacked manually or transported via a conveyor system.

This partially automated process reduces manual effort while ensuring high accuracy and efficiency in bagging operations.

Types of Semi Automatic Bagging Machines

There are different types of semi automatic bagging , each designed for specific materials and industries:

1. Gravity-Fed Semi Automatic Bagging Machine

✅ Best for free-flowing materials like grains, rice, and seeds.

✅ Uses gravity to dispense material into the bag.

2. Auger-Based Semi Automatic Machine

✅ Ideal for fine powders such as flour, cement, and chemical powders.

✅ Uses an auger screw system for precise material dosing.

3. Pneumatic Semi Automatic Machine

✅ Suitable for lightweight materials that need air compression for easy filling.

✅ Commonly used in pharmaceutical and food industries.

4. Belt Conveyor Semi Automatic Machine

✅ Best for bulkier materials that require conveyor movement.

✅ Helps in transporting filled bags to the sealing station.

Each of these types offers specific advantages, allowing businesses to choose the right machine for their operational needs.

Key Features of a Semi Automatic Bagging Machine

✔ User-Friendly Operation – Requires minimal training for operators.

✔ Accurate Weighing System – Reduces product wastage and ensures consistent packaging.

✔ Flexible Bagging Capacity – Can handle various bag sizes and materials.

✔ Cost-Effective Automation – Combines manual and automatic operations for optimized efficiency.

✔ Adjustable Filling Speeds – Allows for customization based on production needs.

✔ Durable and Low Maintenance – Built for long-term industrial use.

With these features, a semi automatic bagging machine is an ideal investment for businesses looking to increase efficiency without full automation costs.

Benefits of Using a Semi Automatic Bagging Machine

✅ 1. Improved Efficiency & Productivity

- Reduces manual labor time and increases output.

- Allows for consistent and accurate filling.

✅ 2. Precision & Accuracy in Bagging

- Advanced weighing systems prevent overfilling or underfilling.

- Reduces material loss and ensures standard packaging.

✅ 3. Cost-Effective Solution

- More affordable than fully automated bagging machines.

- Provides automation benefits without high operational costs.

✅ 4. Versatility Across Industries

- Suitable for food, agriculture, pharmaceuticals, construction, and more.

- Works with different bag sizes and types.

✅ 5. Easy Integration with Existing Systems

- Can be connected to conveyors, sealers, and weighing machines.

- Offers scalability for future automation upgrades.

A semi automatic bagging helps businesses achieve greater efficiency while keeping costs under control.

How to Choose the Right Semi Automatic Bagging Machine

When selecting a semi automatic bagging, consider:

✔ Type of Material – Powder, granules, pellets, or bulk solids?

✔ Bagging Speed – How many bags per hour do you need?

✔ Bag Type & Size – Open-mouth, valve, or laminated bags?

✔ Accuracy & Weighing Requirements – Precision level needed?

✔ Integration Needs – Will you use conveyors or manual handling?

At stitch experts, we offer customized semi automatic bagging to meet your specific production needs.

Why Choose for Your Semi Automatic Bagging Machine?

At stitch experts, we provide:

🔹 High-Quality, Precision-Engineered Semi Automatic Bagging Machines.

🔹 Custom Solutions for Various Industries – Food, Agriculture, Chemicals, and more.

🔹 Advanced Automation Technology – Ensuring efficiency and cost savings.

🔹 Expert Consultation & After-Sales Support – Helping you optimize your packaging operations.

📞 Contact us today to find the best semi automatic bagging machine for your industry! 🚀

Conclusion

A semi automatic bagging machine is a perfect solution for businesses looking to increase packaging efficiency without investing in a fully automated system. Whether you’re in agriculture, food processing, construction, or pharmaceuticals, these machines provide precision, cost-effectiveness, and improved productivity.

At stitch experts, we specialize in providing custom, high-performance semi automatic bagging solutions.

📞 Get in touch today for a free consultation and pricing details!