Stainless Steel Screw Conveyor

Stainless Steel Screw Conveyor

Stainless Steel Screw Conveyors are designed for transporting bulk materials with precision, ideal for industries like food processing and chemicals.

Send An Enquiry!

Additional Information:

Stainless Steel Screw Conveyor – The Ultimate Solution for Bulk Material Handling

In industries that require efficient, hygienic, and precise material transport, the stainless steel screw conveyor stands out as a reliable solution. Whether in food processing, chemical industries, pharmaceuticals, or agriculture, these conveyors provide seamless and controlled movement of bulk materials.

With its stainless steel construction, this type of conveyor ensures durability, corrosion resistance, and hygiene, making it the perfect choice for industries dealing with sensitive or abrasive materials.

What is a Stainless Steel Screw Conveyor?

A stainless steel screw conveyor is a type of mechanical conveyor system designed to transport bulk materials through a rotating helical screw blade (also known as an auger). This system efficiently moves materials horizontally, vertically, or at an incline, depending on industrial requirements.

Industries That Benefit from Stainless Steel Screw Conveyors:

✔ Food & Beverage – Ensures sanitary transport of powders, grains, and food ingredients.

✔ Pharmaceuticals – Maintains hygiene while moving raw materials.

✔ Chemical Industry – Resistant to corrosive substances.

✔ Agriculture & Farming – Ideal for grains, animal feed, and fertilizers.

✔ Mining & Construction – Handles bulk cement, sand, and minerals.

If you’re looking for an efficient, low-maintenance, and hygienic conveying solution, the stainless steel screw conveyor is the ideal choice.

How Does a Stainless Steel Screw Conveyor Work?

The working principle of a screw conveyor is simple yet highly effective:

1️⃣ Material enters the conveyor through an inlet.

2️⃣ The rotating screw (auger) moves materials forward.

3️⃣ The enclosed structure prevents contamination and ensures smooth transport.

4️⃣ Materials are discharged at the outlet, maintaining a controlled and continuous flow.

This design ensures minimum spillage, reduced dust generation, and maximum efficiency in transporting powders, granules, and bulk solids.

Types of Stainless Steel Screw Conveyors

Choosing the right type of screw conveyor depends on your industry and material handling needs. Here are some common variations:

1. Horizontal Stainless Screw Conveyor

✅ Best for moving bulk materials over short to medium distances.

✅ Used in food processing, grain handling, and powder transportation.

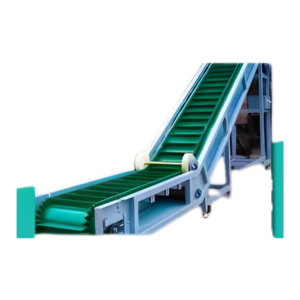

2. Inclined Stainless Screw Conveyor

✅ Designed for lifting materials to different levels.

✅ Perfect for mixing and transferring bulk solids.

3. Vertical Stainless Screw Conveyor

✅ Ideal for upward material transport.

✅ Maximizes space utilization in compact industries.

4. Shaftless Stainless Screw Conveyor

✅ Handles sticky, viscous, and wet materials with ease.

✅ Common in wastewater treatment plants and chemical industries.

5. Tubular Stainless Screw Conveyor

✅ Enclosed system to prevent material loss and contamination.

✅ Highly effective in food, pharmaceutical, and chemical applications.

Each of these screw conveyor types offers unique advantages, ensuring that industries can choose the perfect solution for their bulk material handling needs.

Key Features of a Stainless Steel Screw Conveyor

✔ Constructed from High-Grade Stainless Steel – Provides corrosion resistance and hygiene.

✔ Customizable Sizes & Configurations – Tailored to suit specific industry needs.

✔ Energy-Efficient Design – Reduces power consumption and operational costs.

✔ Hygienic & Easy to Clean – Perfect for food-grade and pharmaceutical applications.

✔ Handles a Variety of Materials – From powders and granules to wet and semi-solid materials.

✔ Minimal Maintenance Requirements – Ensures long-lasting, uninterrupted operations.

By investing in a stainless steel screw conveyor, industries can optimize efficiency, reduce manual labor, and improve overall material handling processes.

Benefits of Using a Stainless Steel Screw Conveyor

✅ 1. Ensures Hygienic & Contamination-Free Material Transport

- Made from food-grade stainless steel, making it ideal for food and pharmaceutical industries.

✅ 2. Provides Exceptional Corrosion Resistance

- Stainless steel prevents rusting and degradation, making it perfect for harsh environments.

✅ 3. Handles a Wide Range of Bulk Materials

- Moves materials gently and efficiently, minimizing waste and spillage.

✅ 4. Customizable for Industry-Specific Needs

- Available in various diameters, lengths, and incline options.

✅ 5. Energy-Efficient & Cost-Effective

- Reduces manual labor, enhances productivity, and lowers operational costs.

✅ 6. Easy to Maintain & Clean

- Minimal moving parts lead to reduced wear and tear.

With these benefits, the stainless steel screw conveyor is a smart investment for businesses looking to streamline bulk material transportation.

How to Choose the Right Stainless Steel Screw Conveyor

When selecting a stainless steel screw conveyor, consider:

✔ Material Type & Flow Characteristics – Powdery, granular, sticky, or abrasive?

✔ Required Capacity & Throughput – How much material needs to be transported?

✔ Conveyor Length & Incline Angle – Horizontal, inclined, or vertical?

✔ Environmental Conditions – Indoor, outdoor, corrosive, or food-safe applications?

At stitch experts, we offer customized stainless steel screw conveyors to meet your specific industrial requirements.

Maintenance Tips for Stainless Steel Screw Conveyors

🔧 Regularly Inspect Bearings & Seals – Ensures smooth operation and prevents material leakage.

🔧 Lubricate Moving Parts – Reduces wear and extends lifespan.

🔧 Clean the Conveyor Thoroughly – Prevents contamination, especially in food and pharma industries.

🔧 Check for Screw Wear & Tear – Replace parts as needed for optimal performance.

Following these maintenance practices will prolong the life of your screw conveyor and reduce downtime.

Why Choose for Your Stainless Steel Screw Conveyor?

At stitch experts, we specialize in manufacturing high-performance stainless steel screw conveyors tailored to your industry’s needs.

🔹 Custom Engineered Solutions – Designed to match your unique material handling requirements.

🔹 Premium-Quality Stainless Steel Construction – Ensures hygiene, durability, and efficiency.

🔹 Energy-Efficient & Cost-Effective Designs – Reduces operational costs and maximizes productivity.

🔹 Expert Support & Maintenance Services – Provides ongoing technical assistance.

🔹 Trusted by Leading Industries Worldwide – Proven track record of reliability and excellence.

📞 Contact us today and let us help you find the perfect stainless steel screw conveyor for your business! 🚀

Conclusion

A stainless steel screw conveyor is a vital component for efficient bulk material handling. Its hygienic design, corrosion resistance, and low maintenance requirements make it the preferred choice for industries dealing with powders, granules, and semi-solid materials.

At stitch experts, we provide custom screw conveyor solutions designed for optimal performance and durability.

📞 Reach out to us today to discuss your specific requirements and get the best solution for your industry!